APOLLO FYM - SPREADER CONTROLLER

15

With the appropriate sensor option highlighted on the "SPEED FACTOR" page, press ENTER, then select

"Auto Cal

'. Press

and then follow the screen instructions.

Stop the vehicle when the second marker lines up with the pre-determined reference point on the vehicle and

press to end the "Auto Cal" procedure. The Speed Sensor Factor is automatically re-calculated and

stored in memory.

NOTE: If you overrun the marker, do not simply reverse - repeat the "Auto Cal" procedure from the beginning.

5.2.3 Wheel sensor calibration - manually calculating the Forward Speed Factor

The smaller the speed sensor factor the better the speed update will be. Aim for a factor less than 2.000 m

(78.78").

NOTE: Perform the following calculations in inches or metres depending on whether the instrument is set for Imperial

or Metric units. If you calculate the factor using any other unit of measurement e.g. feet or centimetres, the

forward speed display will be incorrect.

(i)

If a single magnet is installed (as with a standard RDS Propshaft Sensor kit),

the distance travelled for

each turn of the prop shaft must be determined. To determine this distance, drive the vehicle forwards for

exactly

10

revolutions of the prop shaft. Measure this distance (in inches or metres) and divide by

10

, to find

the Speed Sensor Factor.

(ii)

If 2 magnets are installed (as with a standard RDS Wheel Sensor kit)

, the distance is 1/2 the effective rolling

circumference of the wheel. To determine this circumference, drive the vehicle forward in field conditions (with

the implement attached if applicable), for exactly

10

revolutions of the sensed wheel. Measure this distance (in

inches or metres) and divide by

20

to find the Speed Sensor Factor.

(iii)

If 4 wheel magnets are installed

, the distance is 1/4 the effective rolling circumference of the wheel. To

determine this circumference, drive the vehicle forward in field conditions (with the implement attached if

applicable), for exactly

10

revolutions of the sensed wheel. Measure this distance (metres) and divide by

40

to

find the Speed Sensor Factor.

Carry out this test whenever soil conditions or wheel sizes change.

If the calibration factor works out at over 2.000 m (78.78 inches), consider fitting additional magnets. Extra

magnets are recommended if the vehicle has large diameter wheels or is slow-moving. In extreme

circumstances you can find that the speed keeps going to zero as it times out before the next pulse arrives.

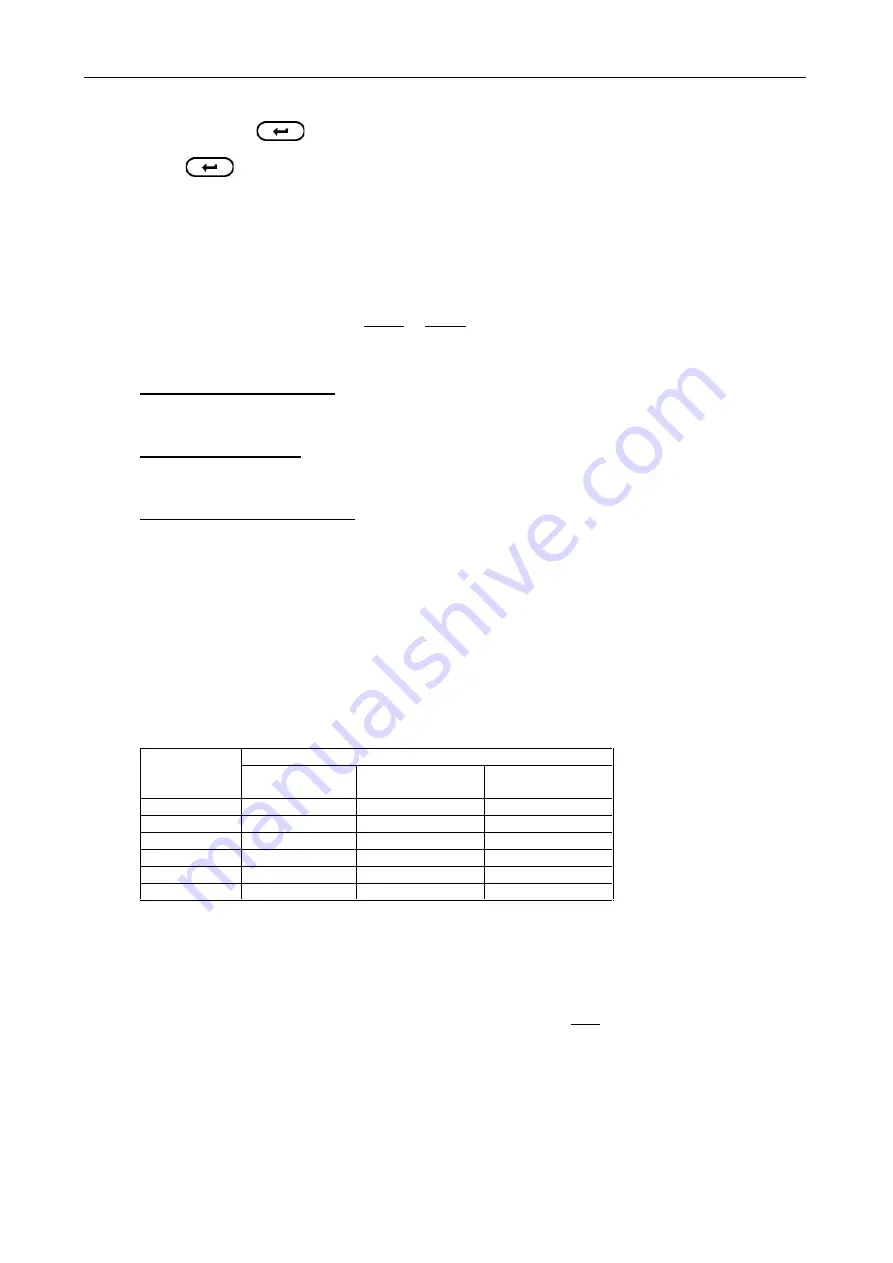

Number of magnets required

The table gives the number of magnets required to enable a speed update of approximately 1 Hz or greater on

the display.

Tyre diameter

Typical speed in normal operation:

up to 5mph

(8km/hr)

6 to 9 mph

(9 to 15 km/hr)

10mph (16 km/hr)

or over

12" (0.3m)

1

1

1

24" (0.6m)

1

1

1

36" (0.9m)

2

2

1

48" (1.2m)

4

2

2

60" (1.5m)

4

4

2

72" (1.8m)

4

4

2

Example Calculation

A vehicle is fitted with a single magnet mounted on the propshaft. The measured distance for 10 rotations of

the sensed wheel is 47'-6".

1. Convert the distance to inches :- (47' x 12")+6" = 570"

2. Divide by 10 (magnet pulses) to give the calibration factor:- 570" / 10 = 57.0"

3. Programme the factor '057.0' as described overleaf.

5.2.4 Radar Sensor

If an RDS Radar sensor is installed at the correct angle of 37±1°, the Speed Sensor Factor is

0.0078

m (or

0.312

inches). It is still recommended to do an ‘Autocal’ since the sensor may not be mounted exactly at 37°.