APOLLO FYM - SPREADER CONTROLLER

14

5.

Spreader Setup

5.1

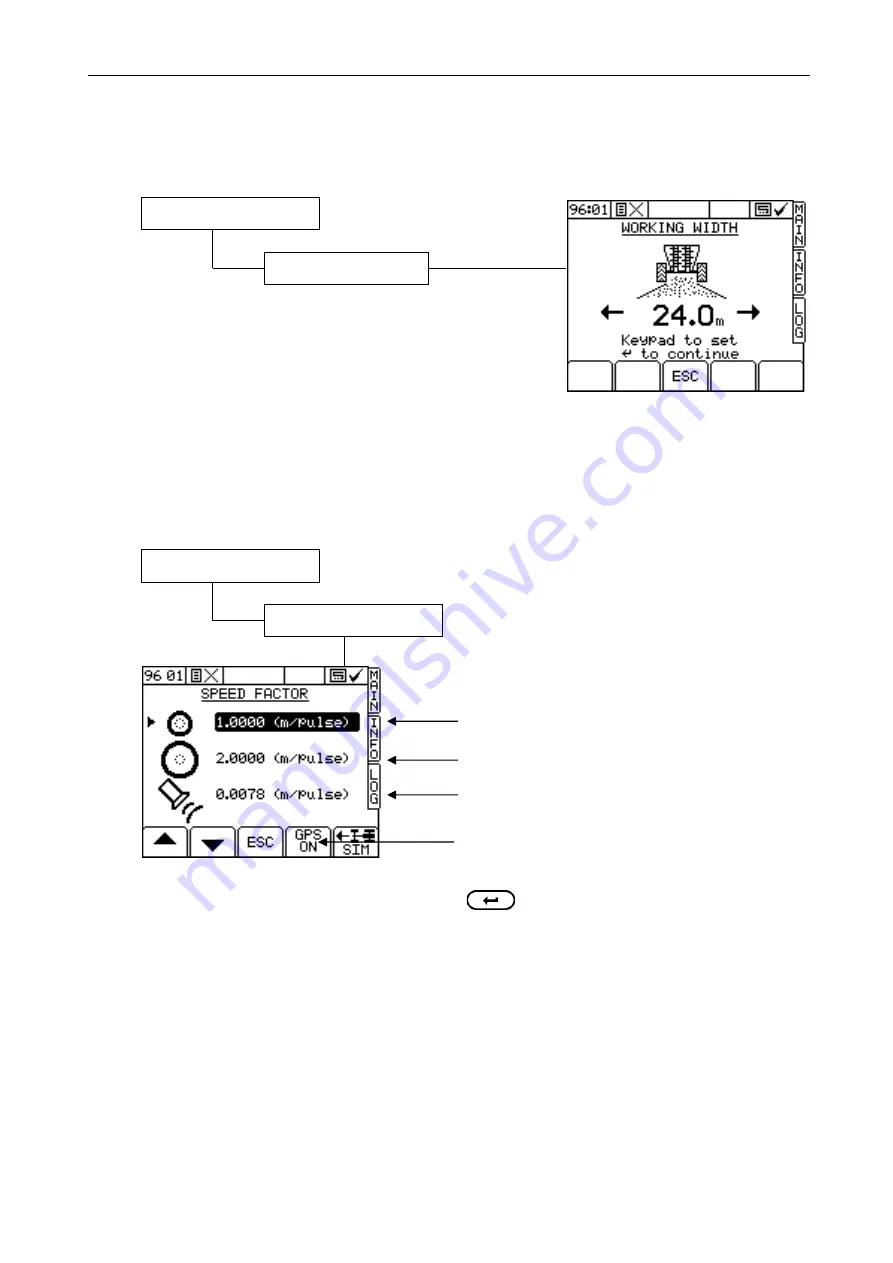

Working Width

5.1.1 Set current Working Width

Using the numeric keypad, type in the current working width and

use the ENTER button to confirm,

5.2

Forward Speed Sensor

5.2.1 Select Sensor Option

2. Move the arrow cursor to select the option and press to confirm.

5.2.2 Wheel sensor calibration – ‘Autocal’

If the Spreader has a standard wheel sensor and magnets installed, you can programme the instrument with

two speed sensor factors - for flotation tyres and for row crop wheels. Remember to select the appropriate

factor after changing wheels.

The Speed Sensor Factor ("SSF") is the distance travelled forward in the time between two pulses from the

forward speed sensor. This could be calculated based on the nominal tyre diameter or rolling distance and

then entered manually (ref. section 1.1.3), however this does not take into account wheel slip, compaction, or

tyre deformation under practical operating conditions.

The best method is to do an "Auto Cal".

Mark a set distance of 100 metres (or 100 yards depending on the units set on the instrument) by suitable

means. The surface should be representative of the average field conditions (i.e. not a paved surface).

Position the vehicle with the first marker level with a suitable reference point on the vehicle.

Wheel Sensor - for flotation tyres

Wheel Sensor - for (larger) row crop wheels

Radar Sensor / RDS ‘Satspeed’ Interface

UK57201.PCX

DGPS input (this option only appears when top port is

configured for GPS input)

1.

Spreader Setup

1.

Working Width

UK572-02.PCX

1.

Spreader Setup

2.

Speed Sensor Factor