APOLLO FYM - SPREADER CONTROLLER

9

2.2

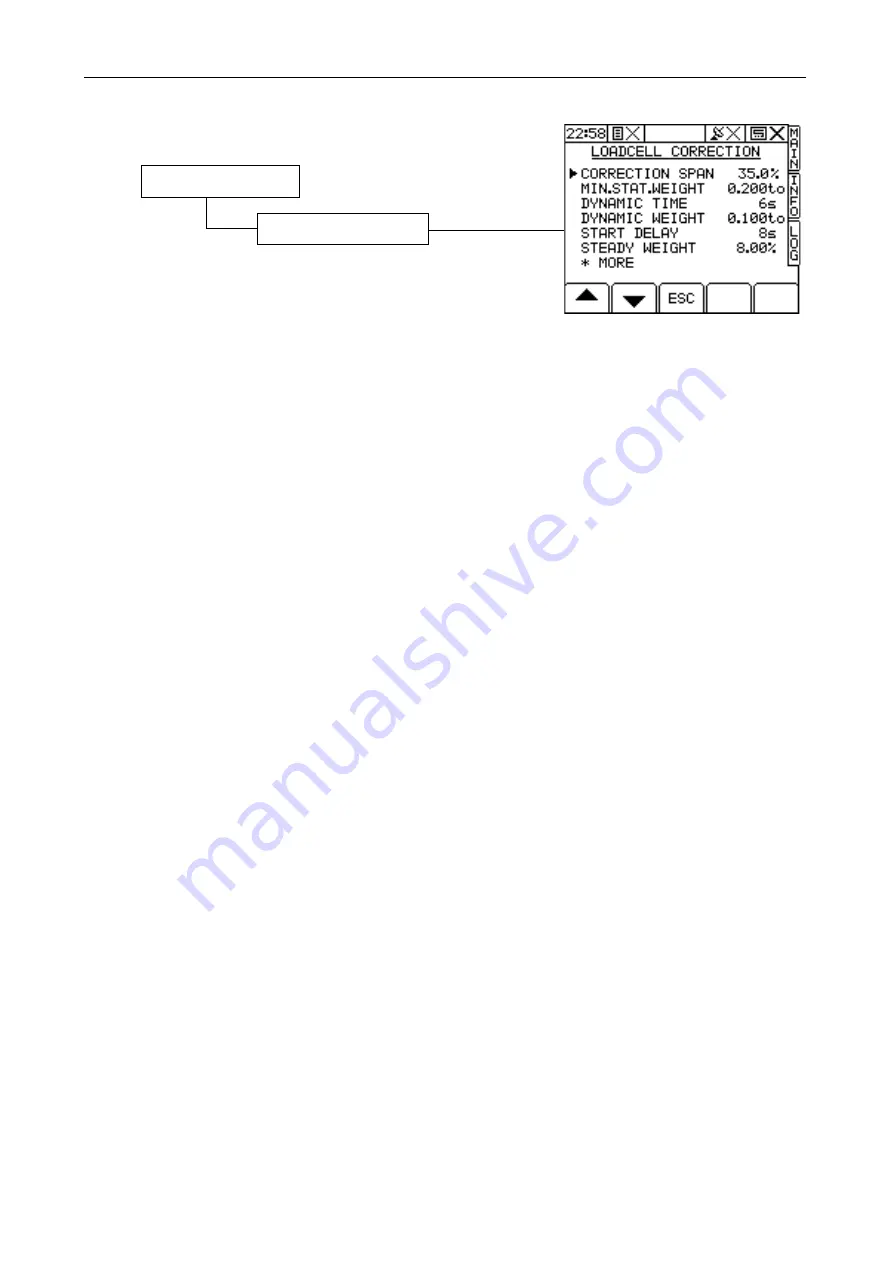

Loadcell Correction

Figure 22

"Boom/Cutouts Inputs" page

Correction Span

This is the amount that the T factor can be allowed to change by after each dynamic calibration test. If this

figure is too large, floor speed correction may vary significantly, affecting the spread pattern and possibly

overloading the driveline.

Min Stat Weight

This is the amount of product that must be spread during a static test.

Dynamic Time

This is how often a DYNAMIC correction is made to the calibration.

Dynamic Weight

This is the amount of product that must be spread during each DYNAMIC correction.

Start Delay

This is the pause time at the start of each new load to allow for the product to reach the beaters before the

system starts to make any corrections. This time should be longer than the pre-start time if that function is

being used.

Steady Weight

This is the % change that is allowed each second before the system will be deemed to have an unstable

weight reading.

H’Land Delay

This is the pause time at start of each new headland turn (if the hopper has not been filled) before the system

will resume DYNAMIC corrections. This is to give the floor time to get to speed.

T Factor Delay

This is the pause time after each new DYNAMIC correction has been made before the new correction starts,

this allows the floor time to react to the new factor before starting to calculate the next correction.

T Store Mode

This defines whether MANUAL or AUTO T factor reset is being used. When the hopper has been refilled then

the T factor (ref. section 4.1.3) gets automatically reset to a higher figure to allow the floor to move at a normal

speed. In AUTO this is automatically calculated from a point in the last load.

Dyn Fill Weight

This is the amount that the hopper weight must increase by to know that it has been filled up again.

Dyn Min Weight

This is the amount at which DYNAMIC corrections will stop, eg, once you are under 1t of weight in the hopper.

T Store Auto

This is the weight at which the system will store its T Factor (ref. section 4.1.3). The system will remember its T

factor when it was at this weight and reset to this once the hopper has been filled.

Corr Span Fast

This is the amount that the T factor can be allowed to change by after each dynamic calibration test when the

weight is below the ‘Fast Empty Point’ as set in the Product Menu.

2.

Technician Config.

2.

Loadcell Correction

UK572-14.PCX