24

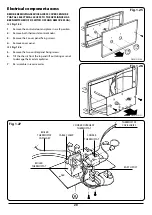

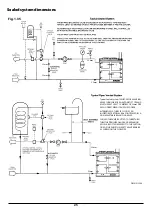

Sealed system requirements

See

Fig. 1.35

A.

The installation must comply with the regulations in

force. Maximum water 82ºC temperature.

B.

An approved safety valve set to operate at 3 bar (44 Ibf/

In2) shall be fitted in the flow pipe close to the boiler.

There must not be any valve between the safety valve

and the boiler. The valve should be positioned on a

discharge pipe fitted to prevent any discharge or creating

a hazard to occupants or cause damage to electrical

components and wiring.

C.

An approved pressure gauge covering at least the range

0 to 4 bar (0 to 60 Ibf/In2) shall be fitted in the system, in a

visible position.

D.

An approved diaphragm type expansion vessel, shall be

connected at a point in the flow pipe close to the boiler.

The vessel must be chosen to suit the volume of the

water in the cistern and the system charge must not be

less than the static head at the point of connection.

Safety Valve

Setting

3.0 bar

Vessel charge

and initial

system

pressure

0.5 bar

1.0 bar

Multiplying

Factor

0.09

0.16

Expansion

Vessel volume

(litres) =

System volume

Vs x factor

L

Vs x

0.0833

L

Vs x

0.109

Vs = System Volume Litres

Sealed System

E.

The hot water cylinder shall be either the direct coil type

or a cylinder fitted with a calorifer which is suitable for

the system pressure.

F. The Make-Up Vessel

Provision shall be made for

replacing the lost water from the system by either of the

following methods:

a.

From a make-up vessel or tank, and connected

through a non-return valve to the system on the

return side of the hot water cylinder or return side of

all heat emitters or radiators.

b.

Where access to a make-up vessel would be difficult,

by a remote automatic pressurisation and make-up

unit.

c. Mains Connection

There shall be no connection to

mains water supply or to the water storage cistern

supplying domestic hot water, even though a non-

return valve may be fitted, without the approval of

the local water authority.

d. The Filling Point

The system shall be fitted with a

filling point at a low level, and be used in accordance

with the local water authority requirement.

e. Commissioning - General

The system shall be filled

by water by a method acceptable to the Local Water

Authority.

Check the operation of the safety valve manually. After

flushing and refilling the system either:-

•

(a) If a make-up vessel is filled release water from the

safety valve until the level in the make-up bottle falls

visibly, then top up the make-up bottle.

•

(b) If there is no make-up vessel either release or

introduce water until the designed cold water pressure

level is reached.

Commissioning

Follow the commissioning instructions as for open vented

systems. See section Commissioning Instructions with the

following additions:-

Fill the system until the pressure gauge registers 1.5 bar

(22Ibf/In2). Clear any airlocks and check for water soundness.

Check the operation of the safety valve, by allowing the

water pressure to rise until the valve opens. The valve should

open within ±0.3 bar (±4.35 Ibf/In2) of the pre-set pressure, if

this is not possible conduct a manual check and test.

Release water from the system until the minimum system

design pressure is reached 1.0 bar if the system is to be pre-

pressurised.

Any set pointer gauge should be set to coincide with the

recommended filling pressure.