April 18, 2018

7080-166B

11

TREKKER

N. Restarting the Appliance

Restart Process

1. When the unit has run out of fuel and the “feed error”

code is displayed, add pellet fuel to the hopper.

2.

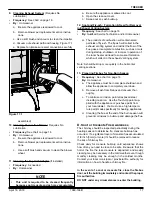

Dump the ashes and clinkers built up in the fire pot by

pulling the ash dump removal handle out several times.

Make sure clinkers have dropped into the ash pan then

return the handle to fully closed position.

3. If needed perform a manual feed; refer to section on

manual feed.

Restarting After a Power Failure

1. For an electrical disruption the appliance will start on

its own without need for MANUAL FEED - providing the

control system is asking for heat.

2. The appliance will always go through a normal shut-

down sequence before restarting.

O. Clear Space

NOTICE:

Clearances may only be reduced by means

ap proved by the regulatory authority having jurisdiction.

Mantel:

Avoid placing candles and other heat-sensitive ob-

jects on mantel or hearth. Heat may damage these objects.

P. Tuning

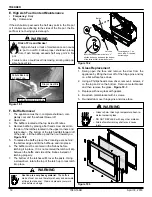

(Factory default setting is 5)

The function of tunning is to allow for variations in

elevation, venting and installation configurations,

and fuel types (hard wood/soft wood).

Figure 11.1

8:30 AM

TUNING

Rotating this dial will adjust the air/fuel ratio to the

appliance:

•

Increase the tunning number to increase the

flame height.

•

Decrease the tunning number to decrease

flame height.

•

Adjust 1 level at a time, allowing 15 minutes

for fire to stabilize before making another

adjustment.

A properly adjusted fire will have a bright, active

flame pattern that extends out of the fire pot approx

-

imately 6 to 9 inches when burning on high. A prop

-

erly adjusted fire will burn cleaner and have higher

efficiencies.

Содержание TREKKER-CSB

Страница 27: ...April 18 2018 7080 166B 27 TREKKER B Maintenance Log Date of Service Performed By Description of Service...

Страница 28: ...28 7080 166B April 18 2018 TREKKER Date of Service Performed By Description of Service...

Страница 29: ...April 18 2018 7080 166B 29 TREKKER Date of Service Performed By Description of Service...