24

24

A

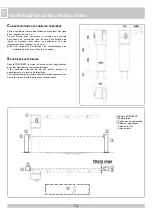

ssEMBLY PLATE TO CEMENT

- Screw down the four bars bent over the plate to cement by using the

washers and the screw nuts supplied with an hexagonal setscrew

wrench no. 19 as shown in figure 1-2.

ATTENTION

: Position the plate to cement keeping attention that it is

laid down perfectly flat and that the point mark is turned

towards the exact position where you want the rod to

come down.

- once you have cemented the plate,

screw down the three long

threaded bars by clamping them energetically with a pliers

as

shown in figures 3-4-5-6.

A

ssEMBLY OPErATOr sUPPOrT COLUMN

- after having screwed down the bars and having pulled the electric

cables for the connections, insert the tube CCa1289 and lean on it the

operator support plate CCa1281. Pull the electric cables up to the top

of the operator support plate as shown in figures 7-8-9.

- Screw down the support plate using the washers and the screw nuts

supplied with a hexagonal setscrew wrench no. 17 as shown in figures

10-11-12.

O

PErATOr fIXING ON THE COLUMN

- Lean the operator on the support plate and fix it by tightening with a

socket head no. 6 the 4 screws supplied as shown in figures 13-14-15.

r

EMOVAL rOD rACK OPErATOr HUB

- remove the hub-cap with a screw no. 5 (Fig. 16).

- Screw off the two screws which block the hub with a screw no. 6 and

remove it from the operator (Fig. 17-18).

A

ssEMBLING Of THE 3 m TELEsCOPIC BOOM

- assemble the telescopic boom fitting the three legs together, until the

screws holes are aligned (Fig. 19-20).

- Secure the Ø 60 leg to the Ø 55 leg with the allen screw 6x70, the two

washers and the self-locking nut. tighten by means of an allen key n°

5 and an exagonal key n° 10.

- Secure the second leg to the third leg with the outfit screws and

washers and insert the end caps into the boom (Fig. 21-22).

Note:

in case the rod needs to be shortened, Do not CUt tHe roD,

nor reMove a LeG. Slide the end leg into the middle leg to obtain

the required overall length, and retighten by means of the outfit screws.

obviously the leg will need to be drilled Ø 5 at its end, and threaded M6

to provided new seats for the outfit screws. the rod can be shortened

up to 2 m without need for balancing.

A

ssEMBLING Of THE 4 m TELEsCOPIC BOOM

- assemble the telescopic rod fitting the 4 legs together, until the screws

holes are aligned (Fig. 19-20).

- Secure the Ø 60 leg to the Ø 55 leg and the Ø 55 leg to the Ø 50 leg

with the allen screw 6x70, the two washers and the self-locking nut.

- Insert the other leg and secure by means of the outfit screws tCeI

6x60, nuts and washers (Fig. 21).

tighten by means of an allen key n° 5 and an exagonal key n° 10.

- Insert the end cap into the end leg Ø 45.

Note:

in case the rod needs to be shortened, Do not CUt tHe

roD, nor reMove a LeG. Slide the end leg into the middle leg to

obtain the required overall length, and retighten by means of the outfit

screws. obviously the leg will need to be drilled Ø 6, 5. the rod can be

shortened up to 3,5 m without need for balancing .

In case a length ranging from 3 to 3,49 m is required, re-balancing of

the rod is necessary.

to re-balance the rod detailed instructions should be obtained from

the address HYPerLInK «mailto:[email protected]» [email protected] or

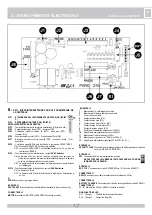

PrEsIDENT AssEMBLY

G

B

COMMAND TYPE

USE OF THE BARRIER

Skilled persons

Skilled persons Unrestricted use

(out of a public area*)

(public area)

with manned operation

A

B

with visible impulses (e.g. sensor)

C

C

C and D

with not visible impulses

(e.g. remote control device)

C

C and D

C and D

automatic

C and D

C and D

C and D

* a typical example are those shutters which do not have access to any public way.

A: Command button with manned operation (that is, operating as long as activated), like code

ACG2020.

B: Key selector with manned operation, like code ACG1010.

C: Built-in Encoder (operating as thrust limitation device, within the limits indicated by specification

EN12453 - Appendix A).

D: Built-in Encoder (operating as presence detector).

Components to install according to EN12453 standards

TECHNICAL

DATA

Max. boom lenght

opening time

Max. torque

Power supply

Capacity

Power absorbed

actuator weight

Protection grade

operating temperature

PrEsIDENT

m

3

4

s

3

3,5

nm

100

130

230V~ 50/60Hz

W

74

a

0,320

kg

40

°C

-10 ÷ +55

IP

44

Power supply

Capacity

Power absorbed

120V~ 60Hz

W

72

a

0,6

Daily cycles suggested

Service

Consecutive cycles guaranteed

normative cycles

n°

∞ - 3s/2s

100%

n°

600

n°

600

400