28

28

doesn’t close only in case the clock function is active. (see

oPenInG 1 button).

s

AfETY fITTINGs OPErATION

sECUrITY LOCK

For a correct functioning of the system, the DL4 led must always be on to

signal that the manual release has not been activated. If the DL4 led is off no

movement of the bar is allowed because it has been manually released with

the special key.

ENCODEr

It has the duty to act as security and to define the running, both during the

closing and the opening phase, with reversal of the movement.

It is possible to exclude the enCoDer, which only functions as security,

through DIP 7 (oFF). In case the enCoDer should not work (not fed,

disconnected wires or faulty) the movement of the bar is not carried out.

If after a first intervention of the enCoDer in closing or opening phase there is

a second one, obviously in the contrary sense, the bar stops and then reverses

for 1 sec. the bell (buzzer optional) will be activated to signal the alarm state

for 5 minutes and the flashlight will be active for a minute.

During or after the 5 minutes of sounding alarm (buzzer optional), it is possible

to reset the functioning of the bar by pressing any control button.

PHOTOELECTrIC CELL (terminals 3-4)

When the bar is down, if there is an obstacle in the radium of the photoelectric

cells and the opening command is given, the bar opens (during the opening

phase the photoelectric cells will not work).

the photoelectric cells will only work during the closing phase (with reset of the

reverse motion after a second even if they are busy).

N.B.: Every six months make sure to check that photocells are not out

of order.

ATTENTION: In case the receiver led remains lit,

malfunctioning of the main supply is suspected.

It is advisable to connect electrically the photocells

stands to the contact 10, to shield the photocells

from external noise.

Be careful not to short circuit the system when the

supply phases are inverted!

sTOP BUTTON (terminals 3-5)

During whatever operation the StoP button stops the bar.

If pressed when the bar is completely open the automatic closing is temporarily

excluded (if selected through DIP3). It is thus necessary to give a new

command to make it close again.

at the following cycle the automatic closing function is reactivated (if selected

through DIP3).

fLAsHLIGHT (terminals 9 positive / 13 negative)

N.B.: This electronic board can feed ONLY fLAsHLIGHTs WITH

LIGHTENING CIrCUIT and a 24V lamp.

the flashlight is active during the motion of the bar, or to signal the impact alarm

state for 1 minute.

Use a flashlight (code aCG7061) with a max. 24v 20W lamp.

BUZZEr (Optional - terminals 3 positive / 12 negative)

During the opening and the closing phase the buzzer will give a sounding

intermittent signal.

In case of intervention of the securities (alarm) this sounding signal increases

the frequency of the intermittence.

Power provided for the functioning of the 200ma buzzer at 12vdc.

T

ECHNICAL CHArACTErIsTICs

- Humidity

< 95% without condensation

- Feeding tension

230v~ ±10%

- Frequency

50/60 Hz

- Battery feeding

20-24,5vdc

- transformer power

130va - v primary 230 vac -

v Secondary 18vac

- Standby modus

100ma

- network micro interruptions

100ms

- Flashlight max. load

24vdc 20W

- Power available for per photoelectric cells and fixtures

1a ±15%

- Power available on radio connector

200ma

- all the inputs must be used as clear contacts because the power supply is

generated inside (safe power) the control panel, and it has been laid down in

such a way to guarantee a double or strengthened insulation in relation to the

parts with dangerous power.

- eventual external circuits connected to the outputs of the control board

or of the expander card must be carried out making sure that a double or

strengthened insulation is used in relation to parts with dangerous power.

- all inputs are run by a programmed integrated circuit which does a self check

every time it starts operating.

G

B

T

rOUBLE sHOOTING

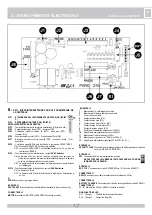

after having carried out all connections, by carefully following the layout and having positioned the bar in intermediate position, check the correct ignition of LeDS DL2,

DL3, DL4; the led DL1 can be ignited or extinguished.

In case of no ignition of the LeDS, always with bar in intermediate position, check the following and replace any faulty components.

DL1 switched off Faulty encoder

DL2 switched off Faulty Stop button

DL3 switched off Faulty photocells

DL4 switched off Faulty manual release or unblocked bar.

During functioning with personnel present, with DIP 1 at on, check that during opening the green DL6 LeD switches on and that during closing the red DL7 LeD switches

on. If not, invert the wires of the motor.

after having carried out the various connections and having supplied voltage, all

the LeDS are switched off.

the motor opens and closes, but it has no strength and moves slowly.

the bar opens but does not close after the time set.

the slowing phase is not performed.

Check the integrity of fuses F, F1 and F2.

In case of interrupted fuse use only of adequate value.

F 1,6a

ProteCtIon FUSe tranSForMer (external to the ParK 24v

control board)

F1 = 2a F2 =10a

Check the adjustment of the balancing springs.

Check the trimmer LoW-SPeeD adjustment.

ensure to have enabled DIP 3 at on.

Button oPen 1 always inserted.

replace button or switch of the selector switch.

Check the adjustment of the balancing springs.

Check trimmer LoW-SPeeD adjustment.

fAULT

sOLUTION

24Vdc

Cont.

10