- 38 -

1901-DE Maintenance _2860

MAINTENANCE

EN

• If the

distance (A) is greater than 4 mm then the

bushes (B) on the inside of the tine arms are to

changed. Otherwise subsequent damage may occur

to the machine.

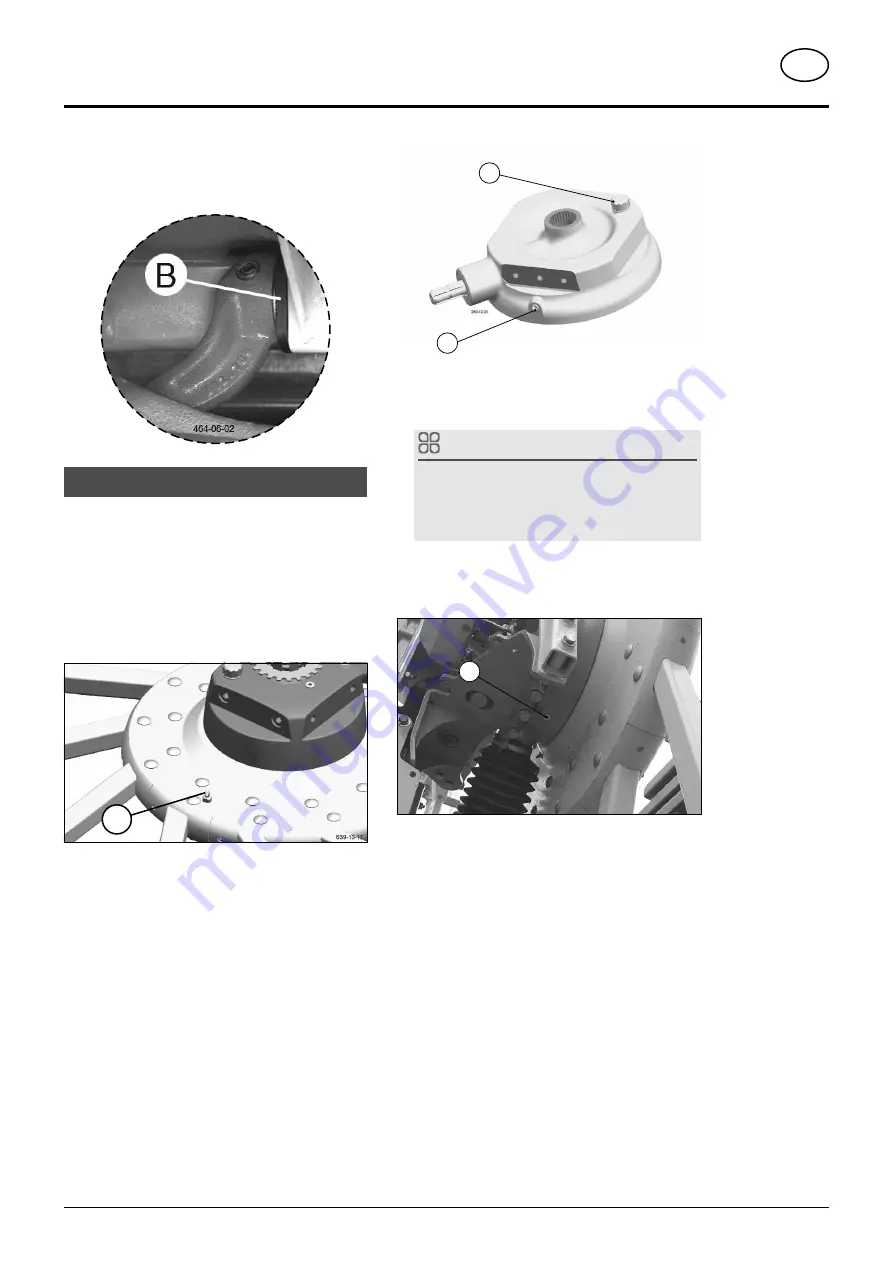

Rotor unit

Curved track

Interval:

50 h

Implementation:

- Put the grease gun on the grease nipple (1)

- Turn the rotor to ensure that the grease is evenly

distributed

- Pump grease gun 3-4 times during a full rotation

- Make 3-4 full rotations

1

TOP 662

Drive of the rotary unit Refill grease

1. Interval:

if needed

The gearbox of the rotary unit is greased for lifetime.

Nevertheless, check once a year whether the cogs still

are covered.

2. Implementation:

1. Open oil filling screw (1). The crown wheel toothing

is easily visible when the filling screw is open.

2. Pour fluid grease in through the filling plug (1) until

the crown wheel is almost completely covered.

3. Close filling screw (1)

4. Distribute the grease by turning on the pto.

5. Check the oil level with the drain plug open. The

crown wheel should be almost completely covered.

6. Continue filling with liquid grease if appropriate, or

reduce the amount of liquid grease via the drain plug

(2).

1

2

Change liquid grease:

1. Interval:

if needed

TIP

Only change the grease when the oil is at operating

temperature.

Draining the grease takes about 3-4h. Maybe do this

overnight or suck it away.

2. Implementation:

1. Bring the machine to transport position

2. Open the drain plug (2)

2

3. Drain the liquid grease.

4. Close the drain plug (2)

5. Continue as in section "Filling with Liquid Grease"