Maintenance

14

3A0441A

Maintenance

Striper

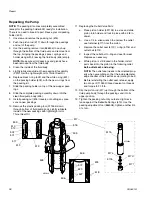

NOTE: Minimum hose size allowable for proper striper

operation is 1/4 in. x 50 ft.

For detailed engine maintenance and specifications,

refer to separate engine manual supplied.

DAILY: Check engine oil level and fill as necessary.

DAILY: Check hose for wear and damage.

DAILY: Check gun safety for proper operation.

DAILY: Check pressure drain valve for proper operation.

DAILY: Check and fill gas tank.

AFTER THE FIRST 20 HOURS OF OPERATION: Drain

engine oil and refill with clean oil. See engine manual for

correct oil viscosity.

WEEKLY: Remove air filter cover and clean element.

Replace element if necessary. If operating in an unusu-

ally dusty environment, check air filter daily and replace

if necessary.

Replacement elements can be purchased from your

local engine dealer.

WEEKLY: Check level of TSO in fluid pump packing nut.

Add 3 to 5 drops if necessary. Keep TSO in nut to help

prevent fluid buildup on piston rod and premature wear

of packings.

AFTER EACH 100 HOURS OF OPERATION: Change

engine oil. See engine manual for correct oil viscosity.

SPARK PLUG: Use only BPR6ES (NGK) or W20EPR-U

(NIPPONDENSO) plug. Gap plug to 0.028 to 0.031 in.

(0.7 to 0.8 mm). Use spark plug wrench when installing

and removing plug.

Swivel Wheel

•

Stripers are factory aligned, but if necessary, loosen

two bolts (128) on swivel wheel assembly just

enough to be able to move the wheel by hand. Align

wheel and re-tighten bolts.

•

Place turnbuckle (43) over the two mounting numbs

on the frame.

•

Pressurize the unit with water and Pioneer’s Pump

Conditioner and spray out several lines with the

swivel assembly in the locked position. Use the turn-

buckle to fine tune the alignment of the wheels until

the stripes are straight.

•

Tighten the jam nuts on the turnbuckle to affix the

turnbuckle length for future reference.

•

Tighten the ratchet handles.

Drive Wheel

Curves and Arcs

•

Similar to the above, except that the swivel wheel

assembly is set at an angle. The swivel assembly

can be adjusted to 30 degrees either side of straight

ahead. If you have arcs that you paint regularly, pur-

chase additional turnbuckles (43) and keep them set

to those arc sizes.

NOTICE

The drive wheel is designed to slip. When adjusting

drive wheel, do NOT over-tighten castle nut (see page

34). Axle could become locked and damage the drive

assembly.

ti15294a

Содержание Brite Stripper 3000SP

Страница 46: ...Notes 46 3A0441A Notes ...

Страница 47: ...Notes 3A0441A 47 Notes ...