PFT continuous mixer HM 2002 Overview - Operation - Spare parts lists

Setting water factor

24

2017-03-14

21.3 Water from water tank

Fig. 22: Booster pump

Fig. 23: Suction strainer complete with

filter screen

Booster pump AV 3000, 230 V, 1 Ph, 50 Hz, 0.6 kW complete

article number 00493686

The connected booster pump ensures the required water pressure

of at least 2.5 bar.

NOTE!

When working from the water tank, the strainer

with filter screen (article number 00136619) has to

be positioned upstream (bleed booster pump).

22 Setting water factor

22.1 Pre-setting the water flow rate

1

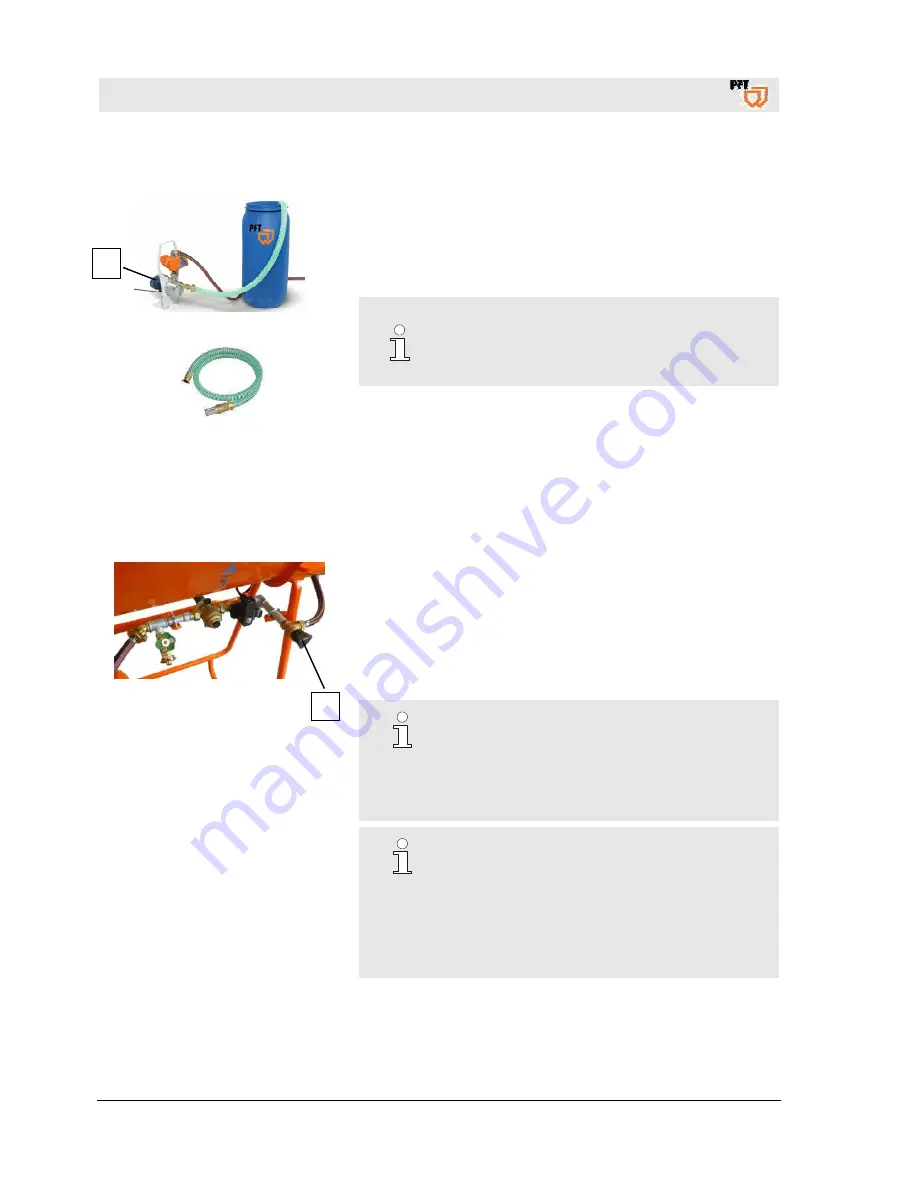

Fig. 24: Needle valve

Adjust the expected amount of water at the needle valve (1):

1. Close the needle valve.

2. Then open the needle valve by two turns.

3. In this position, the water flow rate is approx. 200 ltr/h.

4. Using the needle valve, the material consistency can be

adjusted.

NOTE!

Turning the needle valve in clockwise direction

causes lesser water flow so that the material

becomes viscous and vice versa.

The specifications of the material manufacturer

must be observed here.

NOTE!

Any interruption in the mixing operation results in a

slight irregularity in the consistency of the material.

This irregularity normalises by itself as soon as the

machine has been working for a short while.

Therefore it is important not to change the water

quantity for each irregularity. Wait until the

consistency of the material has set again.

1