Switched Units: Default functions of the control switches

Switch Position

POT

Notes

Factory Default

Configuration.

Run Forward or Reverse

with speed controlled from

the Local POT.

Run Reverse

STOP

Run Forward

Sets the output frequency

NOTE

Other functions are possible, please refer to the online documentation for additional information.

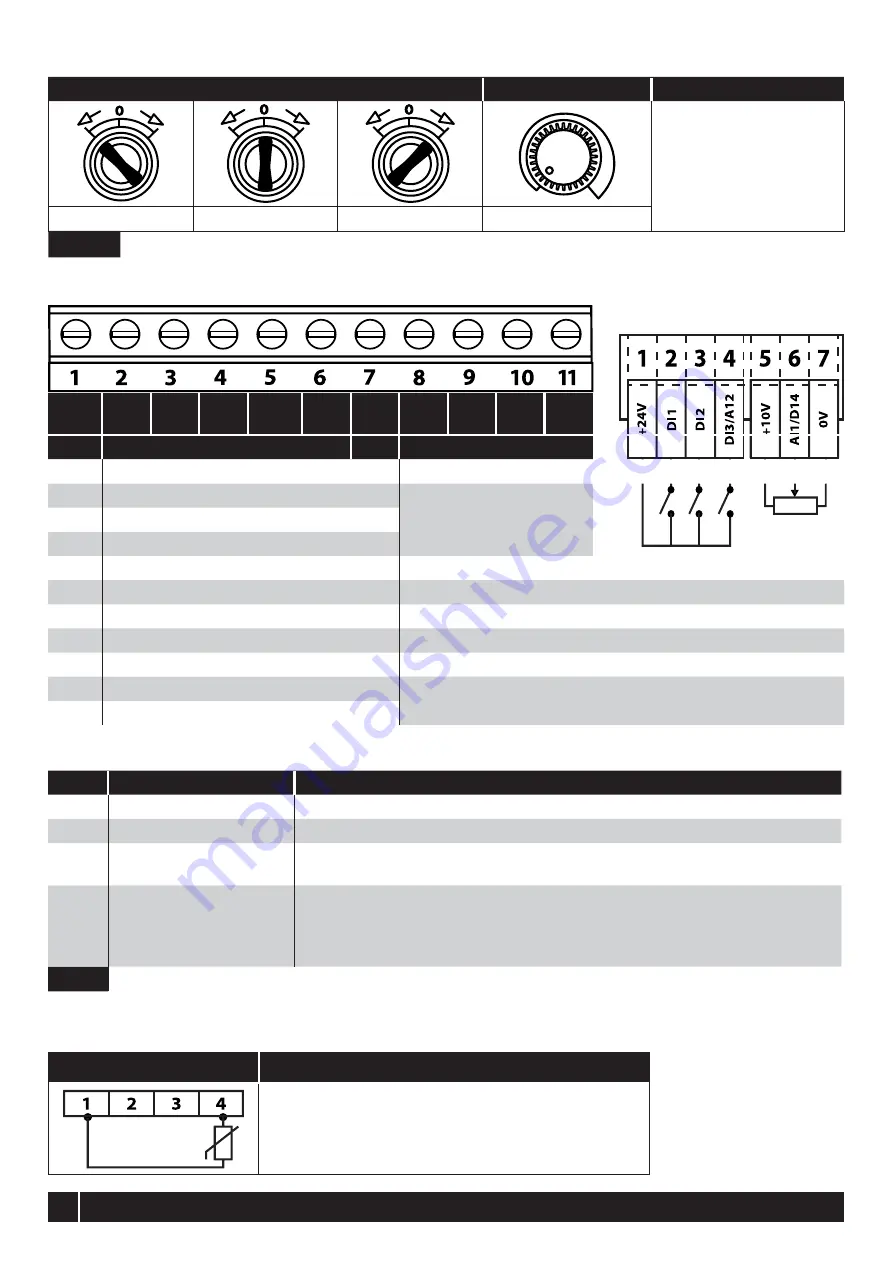

Using the Control Terminals

Connection Example

Factory Default Functions

No.

Description

DI1

0/1

Open : Stop

Closed : Run

DI2

3

/

4

Open : Forward Rotation

Closed : Reverse Rotation

DI3

Analog Speed Reference /

Preset Speed

Open : Speed Reference set by Analog Speed Reference

Closed : Speed Reference set by Preset Speed 1 (P-20)

AI1

Analog Speed Reference

Input

Sets the Speed Reference

NOTE

For Switched units, the internal pot is selected by default in P-16.

For Non-switched units, an external pot or 0 - 10 V reference may be connected. Other

signal types may also be used, set P-16 to the correct format.

NOTE

Additional functions are possible, refer to the online documentation for further information.

Motor Thermistor Connection

Where a motor thermistor is to be used, it should be connected as follows:

Control Terminal Strip

Additional Information

Compatible Thermistor: PTC Type, 2.5kΩ trip level.

Use a setting of P-15 that has Input 3 function as External Trip,

e.g. P-15 = 3. Refer to online documentation for further details.

Set P-47 = “

SWFWK

"

5 CHECK

+24

VDC

DI1

DI2

DI3

AI2

+10

VDC

DI4

AI1

0V

A0

0V

RL1

RL2

Nr.

Purpose

Function

1

+24 VDC 100 mA Output

24 VDC Output

2

DI1 Digital Input 1

Function defined by

P-12 & P-15.

See below for futher info

3

DI2 Digital Input 2

4

DI3 Digital Input 3/AI2 Analog Input 2

5

+10 VDC 10 mA Output

10 VDC Output for external potentiometer

6

DI4 Digital Input 4/AI1 Analog Input 1

Function defined in P-12 & P-15. Signal format selected in P-16

7

0 VDC Common

8

AO Analog Output/Digital Output

Funktion selected in P-25. See Parameter list

9

0 VDC Common

10

RL1 Output Relay

Function defined in P-18. See Parameter list

11

RL2 Output Relay