138

139

The power supply unit included must be used.

The conductance measurement may be strongly affected with third-party power supply units.

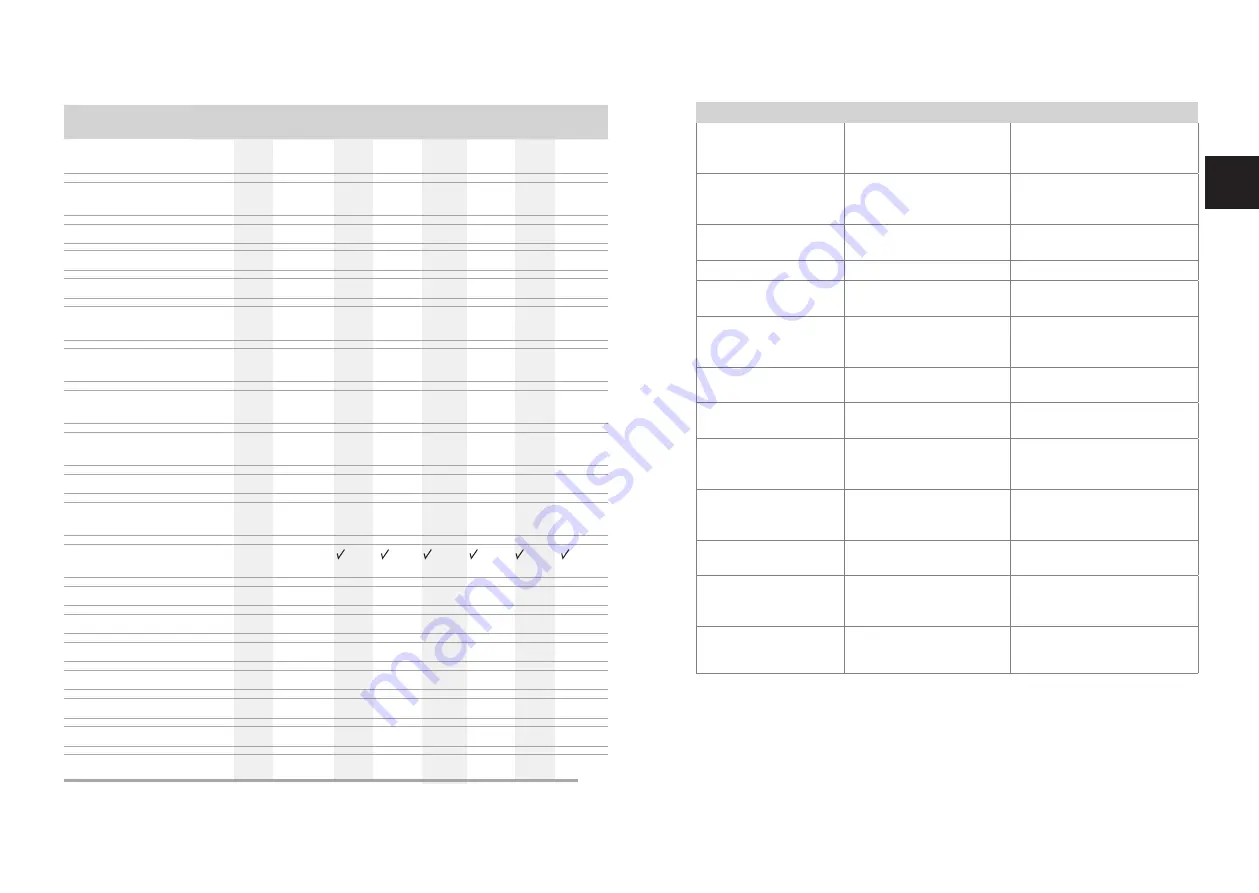

TYPE

PT-DA

1000

PT-DA

5000

PT-DA-CH

5000

PT-DB

1000

PT-DB

5000

PT-DBP

1000

PT-DBP

5000

PT-FCS

5000

PT-FCSD

5000

Supply voltage

in V DC / battery

3

2 x AA

3

2 x AA

3

2 x AA

3

2 x AA

3

2 x AA

24

24

24

24

Power consumption

in W, stand-by / max.

0,1 / 7 0,1 / 7 0,1 / 7 0,1 / 7

Ambient temp. in °C

5-40

5-40

5-40

5-40

5-40

5-40

5-40

5-40

5-40

Protection class

IP 32

IP 32

IP 32

IP 32

IP 32

IP 32

IP 32

IP 32

IP 32

Signal output in V / A

3 / 0,1 3 / 0,1 3 / 0,1

3 / 0,1 3 / 0,1 24 / 0,1 24 / 0,1 24 / 0,1 24 / 0,1

Pulse output

(1 pulse / ltr) V / A

3 / 0,1 3 / 0,1 3 / 0,1

3 / 0,1 3 / 0,1 3 / 0,1 3 / 0,1 3 / 0,1 3 / 0,1

Measuring range

in µS/cm

1 - 99

1 - 99

1 - 99

1 - 99

1 - 99 1 - 99

1 - 99

1 - 99

1 - 99

Connection thread

in DN / inch

15/G ½ 15/G ½ 15/G ¾

15/G ½ 15/G ½ 15/G ½ 15/G ½ 15/G ½ 15/G ½

max. operating temp.

in °C

30

30

30

30

30

30

30

30

30

max. inlet pressure in bar 4

4

4

10

10

10

10

10

10

Regulating range of

pressure reducer in bar

–

–

–

1,5 - 4 1,5 - 4 1,5 - 4 1,5 - 4 1,5 - 4 1,5 - 4

Integrated system

separator

–

–

–

Dimension b1 in mm

255

255

255

353

353

353

353

420

420

Dimension b2 in mm

383

383

383

480

480

480

480

544

544

Dimension h2 in mm

325

690

690

330

700

330

700

700

700

Dimension t in mm

58

58

58

67

67

67

67

67

67

Capacity in °TDS x litres 1000

5000

5000

1000

5000

1000

5000

5000

5000

max. flow rate in l/min 2

7

7

2

7

2

7

7

7

Weight in kg

3,4

6,3

6,3

5,2

8,1

5,2

8,1

8,5

8,5

10. TECHNICAL DATA

EN

11. FAULTS

FAULT

CAUSE

REMEDIAL MEASURE

Flow rate too low or no

flow at all

System separator not

mounted in the flow direc-

tion

Install the system separator

in the flow direction (observe

arrow direction on housing)

Shut-off valves before or

after refilling combination

not fully open

Open the shut-off valves fully

Pressure reducer not set to

the desired outlet pressure Set outlet pressure

Integrated dirt trap dirty

Clean the dirt trap

Flow rate too low during

initial filling

Inlet pressure on the

pressure reducer too low

Increase outlet pressure during

initial filling

Drain valve opens for no

reason (no inlet pressure

fluctuations)

Non-return valve on inlet

side or drain valve dirty

Remove cartridge insert and

clean or replace it

Drain valve doesn't

close

Drain valve is dirty

Remove cartridge insert and

clean or replace it

Water escaping from

the spring cap

Diaphragm valve insert

defective

Replace valve insert

Set outlet pressure does

not remain constant

Nozzle or sealing ring of

the valve insert is dirty or

damaged (through-hole)

Replace valve insert

Conductance traffic light

turns red prematurely

Conductance briefly > 40

µS/cm

Reduce flow rate, in case of

automatic pressure holding

systems use PT-PS28000E

Display is blank

Power supply interrupted

Check battery seating, check

plug contacts of power adapter

Display error/display

doesn't react

Program may be "hung up"

Unplug power adapter for 10

secs. or briefly remove the

battery

Conductance display

shows E1

Conductance sensor defec-

tive (short-circuit)

Replace conductance sensor

Содержание PT-DA-CH5000

Страница 72: ...142 143...