Boiler Control Instruction & Operation Manual, Rev 1

Page

32

of 64

Setup & Tuning

Parameter Adjustment

Table 11:

Response Speed Adjustment Guidelines

Central Heat Continued

Factory

Setting

Range /

Choices

Parameter and Description

130 F

50

– 185 F

Central Heat 4-20mAdc Setup, 4 mA Water Temperature

Sets the Central Heat Temperature Setpoint corresponding to 4 mA.

180 F

50

– 185 F

Central Heat 4-20mAdc Setup 20 mA Water Temperature

Sets the Central Heat Temperature Setpoint corresponding to 20mA.

44

0 to 400

Central Heat P Gain

Proportional Gain value for Sequencer control modes. A larger gain value results in

tighter, more active, PID control. Gain is the primary PID modulation rate tuning

adjustment and provides the immediate modulation rate response. Pick a gain based

on the desired initial response. The burner modulation rate can oscillate if the

Proportional Gain is too large.

45

0 to 400

Central Heat I Gain

Integral gain value For Central Heat control Modes. A larger value makes the Integral

ramp in less time (i.e., faster). Integral is a secondary PID modulation rate tuning

adjustment that ramps the output over time (typically minutes). Based on the selected

Local PID P, select the corresponding (from above table) Integral value. Repeats per

minute between 0.5 and 2.0 are typical. The burner modulation rate can oscillate if

the Integral time is too large.

Outlet

Sensor

Outlet Sensor,

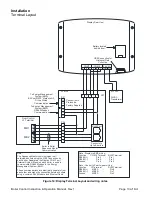

S5 (J8-11)

Sensor

Central Heat Modulation Sensor

Heat Demand may respond to the boiler

’s Supply Temperature or S5 (Header)

Temperature sensors. When Header Sensor is selected the boiler is fired in response

to the sensor wired to Header Sensor terminal J8 terminals 11 and 12.

NOTE

: Outdoor air sensor cannot be selected to use the same terminal.

Local

Local,

4-20mA,

Modbus

Modulation Source

The boiler can modulate (vary boiler heat input) based on local or remote (4-20mA or

Modbus) signals. Modulation begins after the start sequence finishes and the boiler is

released to modulate. Modulation Source has the following selections:

Local Local setpoint and control is used to create firing rate.

4-20mA

Input wired to J8 terminals 6 and 7 is used as modulation rate.

Modbus

Modbus signal is used as modulation rate.