Boiler Control Instruction & Operation Manual, Rev 1

Page

19

of 64

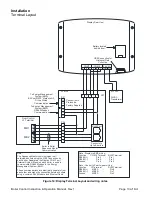

Installation

Terminal Layout

A

B

C

A

B

C

Boiler to Boiler

Sequence Master

Communication

MB1

MB2

From Control

J3 Terminal

2

3

4

10

9

8

60

59

58

57

56

55

2

3

1

4

5

RJ45 Port

Connects to

Up to 8 boilers

Connection to

Protonode

Factory Supplied

P26

P21

P27

N

To Energy Management

System (EMS)

RS485 Modbus

Communication

To Energy Management

System (EMS)

BACnet MSTP, Metasys N2,

Or LonWorks

Communication

Note

The Sequence Master communicates to all

networked boilers using the MB2 Connection on

each boiler. Separately the Display COM 3 port

(Internal System Menu) on each boiler is used to

communicate RS485 Modbus to the Energy

Management System (EMS).

These communications are electrically separate from

each other and make the connection between boilers

using a common RJ45 Module and Ethernet Cable.

Note - Display to EMS wiring;

Function

COM 2 Terminal

RJ45 Terminal

RS485 (+)

Pin 4 -

Pin 1

RS485 (-)

Pin 5 -

Pin 3

Ground

Pin 6 -

Pin 2

Note - Control to Peer-to-peer wiring;

Function

J3 Terminal

RJ45 Terminal

RS485 (+)

MB2 A

-

Pin 8

RS485 (-)

MB2 B

-

Pin 7

Ground

MB2 C

-

Pin 2

PCB-06

COM1

COM2

24 VAC

A

B

C

A

B

C COM PWR

24VAC

Transformer

N +24V

USB Connection for

Historical Data

Collection

Battery located

behind door

Display Rear View

Figure 14: Display Terminal Layout and wiring notes