Boiler Control Instruction & Operation Manual, Rev 1

Page

11

of 64

Product Features

Multiple Boiler Control Sequencer

Control Options

•

Modulating Sensors

1. Header

•

Modulation Setpoint

-

Outdoor Air Reset

-

Warm Weather Shutdown

-

Frost Protection

-

EMS interface

•

Device Control

-

Boiler, System & Domestic

pumps

-

Fresh Air Damper

Return

Water

System

Circulator

DHW

Circulator

Connects to

Up to Eight

Boilers

Header

Temperature

DHW

Temperature

Switch

ONLY

Sequencer Master

A single Control is parameter selected to be the

Sequencer Master. The Sequence Master does

not rotate. The call for heat, outdoor and header

sensors, and common pumps are wired to the

Sequencer Master

“enabled” Control.

Lead/Slave Sequencing

The Sequence Master is independent of the

“Lead” boiler. One boiler is a “Lead” boiler and the

remaining networked boilers are

“Slaves”. When

demand is increasing, the Lead boiler is the first to

start and the Slave boilers are started in

sequential order (1, 2, 3,

…) until the demand is

satisfied. When demand is decreasing, the boilers

are stopped in reverse order with the Lead boiler

stopped last (

…, 3, 2, 1). To equalize the run time

the sequencer automatically rotates the Lead

boiler after 24 hours of run time.

Customized Sequences

Normally, boilers are started and stopped in

numerical order. However, custom sequences

may be established to optimize the heat delivery.

For example, in order to minimize boiler cycling, a

large boiler may be selected to run first during

winter months and then selected to run last for the

remainder of the year.

DHW Two boiler Start

When the Indirect Water Heater (IWH) parameter

is set to

“Primary Piped” and the DHW Two Boiler

Start parameter is set to

“Enabled” two boilers are

started without delay in response to a DHW call for

heat. This feature allows rapid recovery of large

IWH

’s and multiple IWH’s.

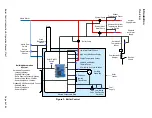

Figure 8: Multiple Boiler Hydronic Options

Shared or Isolated DHW Demand

When the Indirect Water Heater (IWH) parameter

is set to

“Primary Piped” the Sequence Master

sequences all required boilers to satisfy the DHW

setpoint (default 180°F (82.2°C). When

“Boiler

Pipe

d” is selected only the individual slave boiler,

with the wired DHW demand and pump, fires to

satisfy the DHW setpoint

.

Multiple Demands

The Sequence Master responds to Central Heat,

DHW and frost protection demands similar to the

stand alone boiler. For example, when selected

and DHW priority is active, the sequence master

uses DHW setpoint,

“Diff Above”, “Diff Below” and

pump settings. However, the Sequence Master

always uses the Header sensor and does not use

the DHW Sensor.

Optimized Boiler Modulation

Boiler firing rate is managed to increase smoothly as

boilers are started. For example, when a

second boiler is started the initial firing rate is

100%/2 or 50%, when the third boiler is started the

firing rate starts at 200%/3 or 66%. After the initial

start, the Sequence Master develops a unison

firing rate demand based on its setpoint and

header temperature.

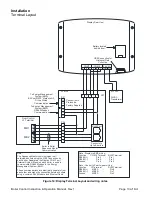

Selecting This Control Mode

Press Configure > Lead Lag Master Configuration;

Select Master enable = Enabled