6

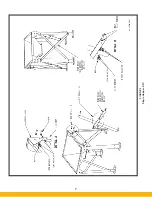

3.3.1.1 Single Module Hopper Assembly

Assemble four leg weldments to hopper (refer to Figure 4, Detail

A), making sure base pads are oriented as illustrated. After four

legs have been bolted to the support hopper, locate the four

support braces which measure 60-11/16” between hole centers,

and attach to left and right side of hopper legs as shown in Figure

4. Locate the two support braces, which measure 55-1/16”

between hole centers. These braces are to be attached to back

legs as illustrated in Figure 4.

After all support braces have been installed. Bolt brace together

as illustrated in Fig. 4, Detail B.

Secure hopper/leg assembly to concrete mounting

pad with appropriate mounting hardware. Anchors

should be provided by customer or contractor

according to local codes.

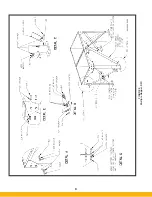

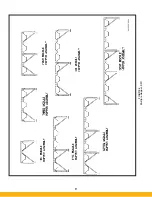

3.3.1.2 Multiple Modular Hopper Assemblies

Position multiple hoppers side by side and bolt through corner

gussets as illustrated in Figure 5, Detail D. After hoppers have

been securely fastened, refer to Figure 6 to locate your hopper

configuration. Using this configuration and Figure 5, Detail E,

locate and attach the leg weldments to the hopper assembly.

Locate the diagonal support brace which measures 60-11/16”

and attach it to the hopper corner brackets on left and right side

of hopper referencing Figure 5 hopper configuration and Figure

6, making sure the base pads are oriented as illustrated in Figure

6. Locate the support braces, which measure 55-1/16” between

hole centers. These braces are to be attached to the back legs

as illustrated in Figure 5, Details A and C.

After all support braces have been installed, bolt side braces

together where they cross as illustrated in Figure 5, Detail B.

Secure hopper/leg assemblies to concrete mounting

pad with appropriate mounting hardware. Anchors

should be provided by customer or contractor

according to local codes.

3.3.2 Fully Assembled Filter Module Sections

Apply two ribbons of sealant to hopper flange to create “figure

8” pattern around mounting holes. Refer to Figure 7, Detail A.

Place filter module onto hopper/leg assemblies (refer to Figure 7).

Drift pins will also be useful for locating the filter module section

onto the hopper.

NOTE: Each hopper assembly is equipped with four 1/2” (13mm)

pry locations – two holes on front flange and two holes

on rear flange. Refer to Figure 7, Detail C, to aid in align-

ing the hopper flange with the module flange.

With filter module still supported, use hardware (refer to Figure 7,

Detail A) to bolt the hopper and filter module together. Securely

tighten all hardware at the filter module and hopper. Recheck leg

assembly sway braces to ensure they are tight. Install fasteners

(bolt, flat washer, lock-washer, nut) to all four pry locations.

Disconnect lifting slings and spreader bars used for installation.

3.3.3 Multiple, Bolt-Together Module Sections

(Applies to 4 or More Modules)

For units that have multiple bolt-together module sections,

remove the row of filters from the modules nearest the bolt-

ing flange (refer to Section 5.1). Protect the doors and filters

removed by placing in a safe area away from work area. Identify

the different module sections. There are left (bolt flange on right

side), right (bolt flange on left side) and possibly center (bolt

flanges on both sides) module sections.

Install all hopper/leg assemblies as previously described in

Section 3.3.1.1 and 3.3.1.2.

Apply two ribbons of sealant to hoppers that are located under

the dust collector section that is being installed (refer to Figure

7, Detail A

CRUSH AND ELECTROCUTION HAZARD

In preparing to attach the filter module to the hop-

per, connect lifting slings and spreader bars to all

filter module lifting lugs with clevis pins. Distribute

the load evenly. Location must be clear of all

obstructions, such as utility lines or roof overhangs.

Place the appropriate filter module onto hopper/leg assembly

to which the sealant has been applied, positioning filter module

corner holes over alignment holes (refer to Figure 7, Detail C).

Drift pins will also be useful for locating the filter module section

onto the hopper.

NOTE:

Each hopper assembly is equipped with four 1/2”

(13mm) pry locations – two holes on front flange and

two holes on rear flange. Refer to Figure 7, Detail C, to

aid in aligning the hopper flange with the module flange.

With filter module still supported, use hardware (refer to Figure

7, Detail A) to bolt the hopper and filter module together.

Securely tighten all hardware at the filter module and hopper.

Recheck leg assembly sway braces to ensure they are tight.

Install fasteners (bolt, flat washer, lock-washer, nut) to all four

pry locations.

!

D A N G E R

!

WARNING

!

WARNING

3.3.1 Hopper Assemblies

The SFC Series filter module is designed to mount directly on

top of the hopper assembly. A hopper assembly consists of

a hopper bin, legs, side diagonal sway braces, rear diagonal

sway braces and the hardware installation kit. Hopper

assemblies will be shipped in pieces and will need to be

assembled at the site.

The hopper sections are shipped in pieces for field assembly.

Position the legs as shown in Figure 4 for single module

hopper assembly, or Figure 5 for multi-modular hopper

assemblies.

Содержание SFC

Страница 1: ...Downward Flow Cartridge Dust Collector Owner s Manual Model SFC...

Страница 7: ...v Page intentionally left blank...

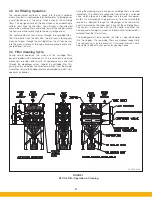

Страница 11: ...4 FIGURE 2 SFC Typical SINGLE UNIT Installation Diagram PARKER PARKER 44 10335 0001...

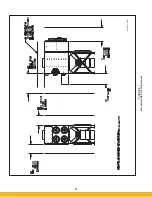

Страница 12: ...5 FIGURE 3 Recommended Unit Clearances 44 10337 0001...

Страница 14: ...7 FIGURE 4 Single Hopper SFC 44 10309 0001...

Страница 15: ...8 FIGURE 5 Multiple Hopper SFC 44 10309 0002...

Страница 16: ...9 FIGURE 6 Multiple Hopper SFC 44 10309 0003...

Страница 17: ...10 FIGURE 7 Multiple Modules SFC 44 10310 0001...

Страница 19: ...12 FIGURE 8 SFC Pressure Gauge Installation 44 10333 0001 Rev A...

Страница 20: ...13 FIGURE 9 Solenoid Wiring to Pulse Controls for 2 3 4 and 5 Tier Units...

Страница 21: ...14 FIGURE 10 Pneumatic Valve Assembly 44 10332 0001...

Страница 24: ...17 FIGURE 12 Abrasive Inlet Installation 44 10338 0001...

Страница 27: ...20 FIGURE 16 EDAP Interconnection FIGURE 15 EDAP Installation 48 10007...

Страница 30: ...23 FIGURE 17 SFC Series Door Filter Installation 44 10329 0001...

Страница 37: ...30 7 Illustrated Parts FIGURE 21 SFC Series 44 10330 0001 FIGURE 22 SFC Series Explosion Vents...

Страница 39: ...32 Page intentionally left blank...