HY28-2668-01/GC/NA,EU

GOLD CUP

®

Series - Application Manual

Piston Pumps & Motors

iv

Parker Hannifin Corporation

Hydraulic Pump Division

Marysville, Ohio USA

Contents

Electrohydraulic stroker (500 series) ....................................................................................3.14

Figure 3.20 Electrohydrauic stroker (zero stroke) .............................................................3.14

Figure 3.21 Electrohydraulic stroker (on stroke) ...............................................................3.15

Figure 3.22 Stroke vs. current ..........................................................................................3.15

Hydraulic stroker (800 series) ...............................................................................................3.15

Figure 3.23 Hydraulic stroker (centered) ..........................................................................3.16

Figure 3.24 Hydraulic stroker (on stroke) .........................................................................3.16

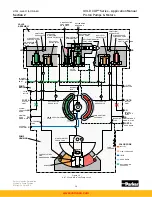

Electrohydraulic servo (HI IQ ) (700 series) .........................................................................3.17

Figure 3.25 Electrohydraulic servovalve (HI-IQ) ...............................................................3.17

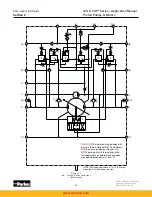

Electrohydraulic stroker (900 series) ....................................................................................3.17

Figure 3.26 900 series hydraulic circuit ............................................................................3.18

Introduction .............................................................................................................................4.1

Remote control of pressure compensator override ................................................................4.1

Figure 4.1 Circuit to control speed of venting compensator ...............................................4.1

Figure 4.2 Remote control of multiple PCOR .....................................................................4.1

Figure 4.3 Remote control of PCOR by pressure sources .................................................4.2

Load sensing ..........................................................................................................................4.2

Figure 4.4 Load sensing .....................................................................................................4.2

Constant speed drives ............................................................................................................4.3

Figure 4.5 Constant speed drive ........................................................................................4.3

Dead man control ...................................................................................................................4.3

Overhauling load-dynamic braking .........................................................................................4.3

Replenishment requirements ..................................................................................................4.4

Figure 4.6 Case pressure replenishment circuit .................................................................4.4

Figure 4.7 Additional replenishment flow ............................................................................4.5

Engine startup ........................................................................................................................4.5

Cold startup ............................................................................................................................4.5

New system or new component startup .................................................................................4.6

System filtration ......................................................................................................................4.6

Cleaning procedures ..............................................................................................................4.7

Shaft type selection ................................................................................................................4.7

Applying splined shafts ...........................................................................................................4.8

Applying keyed shafts .............................................................................................................4.8

Series6 Variable volume pump with 1.07 in

3

/rev., 17,5 cc/rev. aux. pump...............................5.1

Series6 Variable volume motor ...............................................................................................5.2

Series7 Variable volume pump with 1.07 in

3

/rev., 17,5 cc/rev. aux. pump...............................5.3

Series7 Variable volume motor ...............................................................................................5.4

Series8 Variable volume pump with 1.07 in

3

/rev., 17,5 cc/rev. aux. pump...............................5.5

Series11 Variable volume pump with 2x1.07 in

3

/rev., 2x17,5 cc/rev. aux. pump .....................5.6

Series11 Variable volume motor .............................................................................................5.7

Series14 Variable volume pump with 2x1.07 in

3

/rev., 2x17,5 cc/rev. aux. pump .....................5.8

Series14 Variable volume motor .............................................................................................5.9

Series24 Variable volume pump with 2.81 in

3

/rev., 46 cc/rev. aux. pump..............................5.10

Series24 Variable volume motor ...........................................................................................5.11

Series30 Variable volume pump with 2.81 in

3

/rev., 46 cc/rev. aux. pump..............................5.12

Fluid power formulas ..............................................................................................................6.1

Pg1 Pump ordering code ........................................................................................................6.2

Pg2 Pump ordering code ........................................................................................................6.3

Pg1 Motor ordering code ........................................................................................................6.4

Pg2 Motor ordering code ........................................................................................................6.5

Pump control combinations ....................................................................................................6.6

Motor control combinations ....................................................................................................6.7

Notes ......................................................................................................................................7.1

Offer of Sale ...........................................................................................................................7.2

SECTION 3

GOLD CUP

®

controls (continued)

SECTION 4

GOLD CUP

®

application suggestions

SECTION 5

GOLD CUP

®

performance curves

SECTION 6

Reference information

SECTION 7

Offer of Sale

www.comoso.com