HY28-2668-01/GC/NA,EU

GOLD CUP

®

Series - Application Manual

Piston Pumps & Motors

2.1

Parker Hannifin Corporation

Hydraulic Pump Division

Marysville, Ohio USA

Section 2

GOLD CUP

®

series package pumps and motors contain within them all the circuitry normally

required in a hydrostatic transmission. The pumps contain circuitry for the rotary servo actua-

tor, servo pressure relief valve, replenishing relief valve, and pressure compensator override

controls. Package motors contain the shuttle valve and low pressure replenishing relief valve.

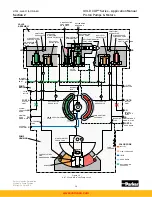

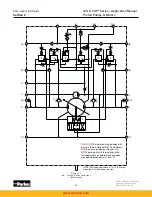

Figures 2.2, 2.3 and 2.4 show the circuitry contained in the GOLD CUP

®

pumps. The circuit in

Figure 2.2 is for the 6.0, 7.25 and 8.0 in

3

/rev pumps. Figure 2.4 is the circuitry for the 24 and

30 in

3

/rev pumps. Figure 2.3 is the circuitry for the 11 and 14 in

3

/rev pumps, which contain a

dual section servo and replenishing pump.

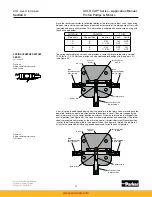

All the pumps in the GOLD CUP

®

line use the same valve block assembly, except that the 30

in3/rev valve block’s servo pressure modulation pin is larger. It contains the pressure compen-

sator override valving for both sides of the pump, the pressure modulated servo relief valve,

replenishing relief valve and replenishing relief pilot stage. The circuitry contained in the valve

blocks and the operation of the individual valves is the same for all pumps. Figure 2.1 shows

the two types of poppets used in the valve block. The stepped poppet is a dual area poppet.

The area on top of the poppet (A

1

) is equal to twice the annular area (A

3

) and twice the area

of the underside of the poppet (A

2

) (the underside area equals the annular area).

The sequence poppet rests on a tapered seat and has only two important areas – the area

above (A

1

) and below the poppet (A

2

). Since the poppet has straight sides and rests on a

tapered seat, both areas are equal.

The sealing of the poppets is realized by floating seats to ensure optimal closure.

In circuits Figures 2.2, 2.3 & 2.4 the servo pressure oil flows from the servo-replenishing

pump to the rotary servovalve. The servo-replenishing pump suction is shown in heavy

blue and is drawn from a reservoir external to the pump. The rotary servovalve action was

described in the Internal Configuration Section and will not be described here. The control

flows from the servovalve are shown in dashed-blue and may be at a pressure less than servo

pressure. Servo pressure is controlled by the pressure modulated servo relief valve in the

valve block.

Output flow from the servo-replenishing pump is exposed to the annular area of the servo

relief valve poppet and after the force created by pressure on the annular area exceeds the

spring force plus the force provided by the pin and replenishment pressure on the top of the

poppet, the poppet will lift and allow flow into the replenishing gallery (green lines). All other

areas of the pressure modulated servo relief valve are exposed to replenishing pressure, as

shown in green. This exposes to replenishing pressure a net area difference on top of the

poppet equal to the area exposed to servo pressure. This makes the pressure modulated

servo relief valve sensitive to replenishing pressure. The pressure setting of this relief valve

is therefore equal to the spring force plus the force generated by the pin on top of the poppet

plus replenishing pressure. Minimum servo pressure is approximately twice replenish and

increases 40 psi, 2,76 bar per 1000 psi, 69 bar as system pressure increases due to the

modulating pin.

(For the 30 series, servo pressure increases 62 psi, 4,14 bar per 1000 psi, 69 bar.) In the 6.0,

7.25 and 8 in

3

/rev pumps (Figure 2.2), the servo pressure gallery is threaded to receive a plug

which is supplied with each pump. If the plug is not used, servo flow is free to travel directly

from the servo-replenishing pump to the servo relief valve.

PACKAGE PUMP CIRCUITRY

Figure 2.1

Poppets

GOLD CUP

®

CIRCUITRY

SERVO AND REPLENISHING

CIRCUITS

www.comoso.com