HY28-2668-01/GC/NA,EU

GOLD CUP

®

Series - Application Manual

Piston Pumps & Motors

3.10

Parker Hannifin Corporation

Hydraulic Pump Division

Marysville, Ohio USA

Section 3

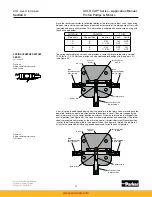

The bypass consists of two tees with integral check valves connected to the high pressure

work ports (see Figure 3.12).

When the bypass is opened, any pressure buildup in the high pressure work ports will open

one of the small check valves and allow flow into the bypass port. This port is open to the

replenishing gallery and the oil flows through the gallery and into the opposite work port at

replenishing pressure.

(400 and 500 series)

When both the input rotary servo control and the rocker cam are coincident in the neutral

position, the ball in the control cover (see Figure 3.12) is held off its seat by the adjustable

pin and a hole in the brake and bypass shoe is open to case pressure. This vents the pres-

sure from two cavities which are connected through small orifices to servo pressure. These

cavities are connected to areas on top of both pistons and the pistons move to the left in the

bore. This opens the brake port to case pressure and permits the long pin to shift, opening the

bypass valve.

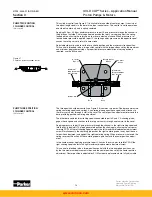

When both the rotary servo input control and the rocker cam are on stroke (see Figure 3.13),

the ball is no longer held off the seat by the adjustable pin (the pin is either moved away from

the ball and seat, or the ball and seat are moved away from the pin) and the hole through the

brake and bypass shoe is plugged off by the servo plate. This stops the flow through the two

orifices and allows pressure to build to servo pressure in the areas to the left of both pistons.

This forces the pistons to the right in their bore, opening the brake port to servo pressure and

closing off the bypass valve with the long pin.

When the input rotary servo is in the neutral position, but the rocker cam is still on stroke (for

example during dynamic braking), the ball is held off the seat, venting the area to the left of

the piston-1; however, the hole in the brake and bypass shoe is still plugged by the servo

plate, keeping servo pressure on piston-2. Piston-2 remains in position, keeping the long pin

blocking the bypass port and the brake port open to servo pressure. This is shown in Figure

3.14.

When the input rotary servo is on stroke and the rocker cam is at zero stroke (for example,

when the rotary servo is initially stroked off of neutral or the transmission is changing direction

of rotation) the ball seats, blocking flow and allows servo pressure to build on piston-1. This

pressure and the light spring force both pistons to the right, keeping the brake port open to

servo pressure and the bypass port closed.

The brake and neutral bypass control has spring centering with a neutral adjustment. The

neutral adjustment can be adjusted for ±5% pump stroke. Adjustable maximum volume

displacement stops are available as an option and can be set anywhere from zero to 100%

stroke. By disassembling the control and adjusting the position of the adjustable pin, the

neutral deadband can be varied. If the pin is shortened (less motion to seat the ball) the

deadband will be reduced.

Figure 3.13

Automatic brake and neutral bypass

400 and 500 series

(input and output on stroke)

S23-12324

M a x . D

i s

p l .

A d j . S c r e w

R o t a r y S e r v o S h a f t

C o n t r o l

C o v e r

M a x . D

i s

p l .

A d j . S c r e w

N e u t r a l Tr

i

m .

A d j . S c r e w

P

i

n

L o n g P

i

n

To R e p l e n

i s

h m e n t

C u

s

t o m e r

S u p p l

i

e d

B r a k e

S e r v o

P l a t e

B y p a

s s

S h o e

B a l l

A d j u

s

t a b l e

P

i

n

S y

s

.

P r e

s s

.

P

i s

t o n - 1

P

i s

t o n - 2

L

i

g h t S p r

i

n g

H e a v y S p r

i

n g

P o r t Z

www.comoso.com