HY28-2668-01/GC/NA,EU

GOLD CUP

®

Series - Application Manual

Piston Pumps & Motors

2.13

Parker Hannifin Corporation

Hydraulic Pump Division

Marysville, Ohio USA

Section 2

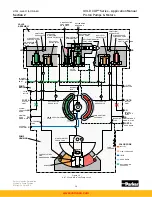

The circuitry provided in the GOLD CUP

®

hydrostatic pumps provides some special features

not found in other transmissions pumps.

1. The servo pressure in the GOLD CUP

®

line varies with system pressure without reducing

control ability. This gives a higher efficiency with a corresponding reduced heat load

to the circuit.

2. There is no need for cross port relief valves external to the pump. The relief sequence valve

circuit in the pressure compensator override circuit accomplishes this function. Should the

pump not be able to continue to change its stroke for any reason, flow from the high pres-

sure work port will go across the high pressure sequence valve, across the dual level relief

valve and into the replenishing gallery where it is carried to the opposite work port.

3. All excess flows from the control valves, with the exception of the rotary servo, are directed

into the replenishing gallery. This prevents momentary loss of replenishing pressure when

the pump is responding to controls.

4. It is possible to prevent momentary cavitation in the pump, at low shaft speed and high

pressure, by connecting case drains from the motor and pump together and passing them

through a 40 psi (2.8 bar) check valve before plumbing to the reservoir. This insures that

should there not be sufficient replenishing flow, the case drain leakages are available for

replenishing. This is due to the replenishing relief valve’s capability of accepting flow from

the case drain into the replenishing gallery, if there is sufficient pressure in the case.

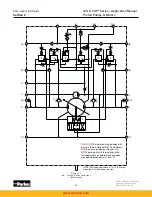

Package motors contain the shuttle valve and the low pressure replenishing relief valve. The

circuitry contained in the motor is shown in Figure 2.5. The shuttle spool is shifted to one

side by system pressure. When shifted the low pressure side of the loop is connected to the

primary side of the low pressure replenishing relief valve. The low pressure replenishing relief

valve is set to a lower pressure than the replenishing relief valve in the pump. This insures

that all the available replenishing flow enters the circuit for cooling. Optional orifices may be

installed in the shuttle-relief block to limit the flow through the shuttle. With the orifices, flow

through the shuttle is limited and the shift is very positive.

PACKAGE MOTOR CIRCUITRY

Figure 2.5

GOLD CUP

®

package motor circuit

www.comoso.com