BA_PH_680-200_EN_11-22.docx

35

10

Mounting and Usage

10.1

Slide Table

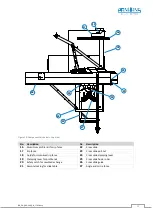

Figure 20: Slide table controls

When the sliding table saw is delivered, the slide table

is already fitted ready for operation.

•

Loosen (pull out) the remote locking device (

21

).

•

Move the slide table to the desired position.

•

Close (press in) the remote locking device (

21

).

You may have to move the slide table slightly for-

wards or backwards so that the lock engages cor-

rectly.

The safety catch (

20

) is used to move the slide table out of the saw blade area (beyond the stop) during a saw

blade change (for more information see chapter

If the machine is not used for a longer period of time, the slide table should be moved to a mid-

dle position. This prevents the rollers from being pressed in.

The slide table must not be locked during a cutting operation.

10.2

Rip Fence

The motorised rip fence is used to feed the workpiece from the rear of the machine (to the right of the saw

blade). The rip fence is already fitted when the sliding table saw is delivered. Only the aluminium profile rail

(

16

) still has to be inserted.

The operation of the rip fence is described in detail in chapter

Important:

For the operation of the rip

fence, please also observe the hazard warnings in the sections

21

20

Figure 21: Fitting the rip fence

Set the aluminium profile rail for normal cuts:

•

Push the aluminium profile rail (

16

) as

far as it will go onto the two fixing

bolts (

a

) of the holding block. The

cross-section must look as shown in

the photo on the left.

•

Fix the aluminium profile rail by

means of the clamp lever (

19

). The

fence (

17

) is now ready for use.

Set aluminium profile rail for inclined saw blade:

•

Push the aluminium profile rail (

16

) onto

the holding block (

b

) rotated by 90°. The

cross-section must look as shown in the

photo on the left .

Warning! Danger of crushing between

aluminium profile rail (16) and rip fence (17).

•

Fix the aluminium profile rail by

means of the clamp lever (

17)

.

19

16

a

17

b