Installation

OMCTT5639E09

17

3.5.4 Argon gas regulator (YX-251A)

The maximum flow rate is 25L/min.

3.5.5 Cooling water unit and cooling water

(1) Cooling water unit (with built-in flow-rate switch)

(2) Cooling water

Use our genuine cooling-water (Pana-coolant K),

which keeps its quality for a long time.

Product number: CWU00098

(Service temperature: -20 to +90 deg-C)

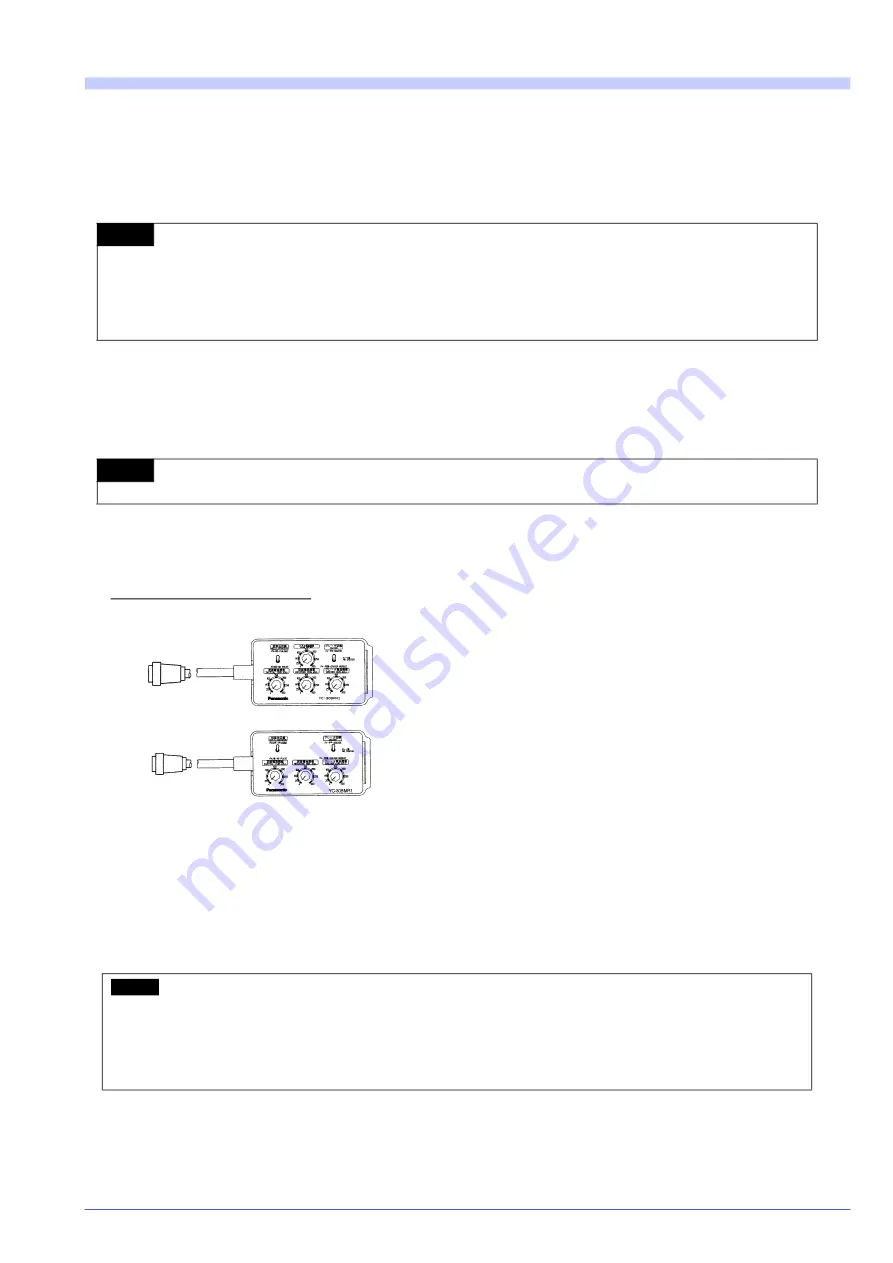

3.5.6 Potentiometer-type remote control unit (YC-30BPR1,YC-30BMR1)

(1) The remote control unit enables you to set the pres

-

ence, absence or repeat of the crater control and the

presence or absence of the pulse control, and to adjust

the initial current, welding current, crater current and

pulse current (Only YC-30BPR1) at a distance. (Cable

length: 5 m)

YC-30BPR1

YC-30BMR1

* After connection of the remote control unit, such

setting and adjustment can be done via the remote con

-

trol unit only.

(2) To have a current value displayed when adjusting each

current, switch the LCD display to the screen of each

current item. Then, the current value of each item

appears on the set-value display.

* Details: See chapter 6 (Name and function of each

part) and chapter 9 (Operation).

* It is also possible to make the adjustment of each

current without switching the LCD display to the screen

of each current item. (In that case, however, no current

value appears on the set-value display.)

(3) As the analog input is employed for the input of current

values from the remote control unit, current values

appearing on the set-value display may vary by about

plus or minus 1A. (It becomes stable if you change the

position of a potentiometer slightly.)

3.5.7 External equipment connection unit (YX-CB009)

• This connection unit enables this welding power source

to change over the pages of stored welding conditions by

connecting with external equipment (sequencer).

• The sequencer is not included in this welding power unit

and the attachment unit.

• When using this connection unit: See”Connection: Con

-

necting to external equipment connection unit”

Note

Cooling water unit

(Product number: YX-09KGC1)

• No flow-rate switch is incorporated in this welding power unit.

• When using a water-cooling torch, use the cooling-water system with a flow-rate switch incorporated to prevent the

torch from burnout.

• Connect the cable of the flow-rate switch to the “water circulation path” terminal of the jig terminal block within this

welding power unit.

Note

TIG welding remote control unit

The conventional YC-301URTRK1 cannot be used. (Due to the difference in connectors and signal lines)

Note

Observe the followings to prevent troubles caused by the incorporation of high frequency waves.

• Keep the signal line connected to the external-equipment attachment unit away from the welding arc area, welding

torch, base-material-side cable, base-material grounding wire, power input line, grounding wire, etc.

• The length of wiring shall be 10m or shorter.

• Make sure to connect the grounding wire of this welding power unit to the ground.

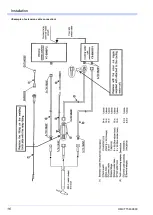

Содержание YC-300BP2YAF

Страница 10: ...Rated Specifications OMCTT5639E09 10 2 2 1 Dimensions ...

Страница 16: ...Installation OMCTT5639E09 16 Example of extension cable connection ...

Страница 49: ...Parts list OMCTT5639E09 49 9 Parts list ...

Страница 52: ...OMCTT5639E09 52 ...

Страница 53: ...Circuit diagram OMCTT5639E09 53 10 Circuit diagram NF9 NF8 ...

Страница 54: ...Circuit diagram OMCTT5639E09 54 10 1 Enlarged left half NF8 MCB ...

Страница 55: ...Circuit diagram OMCTT5639E09 55 10 2 Enlarged right half NF9 ...

Страница 62: ...OMCTT5639E09 62 ...

Страница 63: ...OMCTT5639E09 63 ...