4

BASIC OPERATION

This emblem is used to warn against potential

or unsafe practices which COULD result in

personal injury, and product or property dam-

age if proper procedures are not followed.

CAUTION

This emblem is used to warn against unsafe

practices which COULD result in severe per-

sonal injury or death if proper procedures are

not followed.

CAUTION

WARNING

!

!

25. Keep hydraulic system clean and free from contami-

nants at all times.

26. Use correct anchor for the wire rope size being

installed.

27. Do not use knots to secure or attach wire rope.

28. The BRADEN designed wire rope anchors are capa-

ble of supporting the rated load when installed prop-

erly. For additional safety, ALWAYS maintain a mini-

mum of five (5) wraps of wire rope on the drum. It

is recommended that the last five (5) wraps of wire

rope be painted bright red to serve as a visual

reminder.

29. Never allow anyone to stand under a suspended

load.

30. Avoid sudden “shock” loads or attempt to “jerk” a

load free. This type of operation may cause heavy

loads in excess of rated capacity, which may result

in failure of the wire rope and/or winch.

Safety and informational callouts used in this manu-

al include:

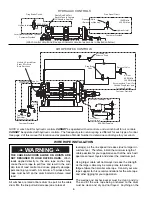

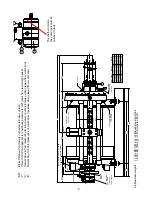

DESCRIPTION OF WINCH

The BRADEN BP200 winch consists of the following

sub-assemblies:

1.

Motor and brake valve block with cartridges

2.

Load holding friction brake assembly

3.

Drum drag brake

4.

Two stage planetary gear set

5.

Cable drum, closure and bearings

6.

Level wind system

7.

Extension shaft

8.

Drum clutch

The BP200 winch is supplied with provisions for either

air or hydraulically operated drum drag and drum clutch

controls. Refer to the “EXPLANATION OF MODEL

NUMBER” to determine the type of control for your

winch. Refer to “WINCH INSTALLATION” for control cir-

cuits.

NOTE: A winch built for air control CANNOT be operat-

ed hydraulically, or vice-versa, without changing the

clutch spring. Consult the BRADEN Service Department

for details.

THEORY OF OPERATION

When the winch is “at rest” with no hydraulic or air pres-

sure applied, the load holding brake is fully applied by

spring pressure, preventing the drum, drive train gears

and motor from rotating. The drum clutch is fully

engaged by spring pressure, and the drum drag brake is

not applied.

BASIC WINCH OPERATION

The winch is built with a solid hub between the input

shaft and the brake discs, which means the load holding

friction brake must be released before the winch will

rotate in either direction. When hydraulic pressure is

applied to either the haul-in or pay-out port, it is routed

to the brake release piston and blocked from flowing

through the motor. The motor cannot rotate until suffi-

cient pressure is present to open the brake valve car-

tridge. The load holding brake within the winch will

completely release at a pressure less than that required

to open the cartridge and allow the motor to rotate.

Once the cartridge is open, the planetary gears, cable

drum and extension shaft will rotate at a speed propor-

tional to the flow of oil to the motor. When the control

valve is returned to the neutral position, pressure will

drop and the cartridge will close, stopping the motor and

the load. As the pressure drops further, the internal load

holding brake is applied by spring pressure, securely

holding the load. In this normal type of operation, the

friction brake receives very little wear. All the heat gen-

erated by stopping a load is absorbed by the hydraulic

oil where it can be readily dissipated.

DRUM CLUTCH

The drum clutch is spring applied, and air or hydraulical-

ly released. The release mechanism is a mechanical

disengagement of the drum from the drive train. The

Содержание Braden BP200

Страница 46: ......