20

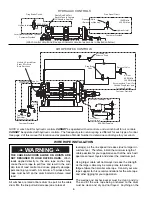

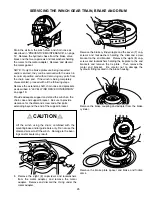

Place a suitable container under the chain case drain

plug and remove the plug to drain the oil. Remove the

vent and reducer bushing from the chain case and clean

them in safety solvent. It is very important to keep the

vent clean and unobstructed.

DO NOT

paint over the

vent or replace it with a solid plug.

The cover removed in this step is under spring tension.

The capscrews should be loosened evenly in a cross-

pattern to relieve spring tension. Remove the six (6)

capscrews and lockwashers holding the diamond screw

disconnect lever assembly to the chain case. Remove

the entire assembly and O-ring under the cover.

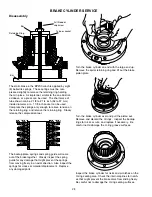

Remove the twelve (12) capscrews and lockwashers

securing the torque tube to the chain case, and slide the

torque tube toward the end of the extension shaft,

exposing the coupling. Remove the nut, washer and

capscrew that are closest to the winch. Carefully

remove the extension shaft and torque tube from the

winch.

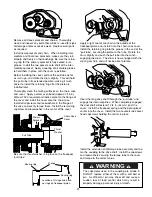

Remove the two (2) socket head capscrews from the

bearing/seal carrier and remove the carrier from the

winch. Remove the freespool spring. The shaft can

now be pulled out of the winch. Some additional oil in

the drum may now drain from the winch.

Remove the external retaining ring at the bottom of the

freespool piston. Remove the freespool piston and

carefully inspect the O-rings, backup rings and sealing

surfaces. Replace the O-rings and backup rings on the

piston if required.

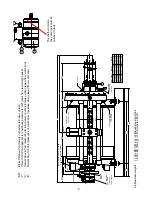

The torque tube and extension shaft weigh approxi-

mately 65 LBS (29 kg). If necessary, provide support

for the torque tube and extension shaft as it is

removed from the winch.

CAUTION

The chain case cover weighs approximately 110 LBS

(50 kg). Provide adequate support as it is removed

from the winch.

CAUTION

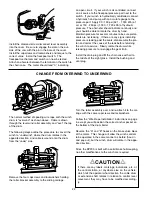

Disconnect the wire from the freespool indicator switch.

Adequately support the chain case cover and remove all

the capscrews and lockwashers from the cover. Note

that there is one capscrew in the center of the cover.

Carefully remove the cover.

Содержание Braden BP200

Страница 46: ......