31

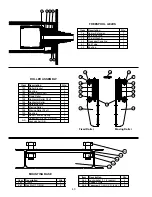

PLANET CARRIER SERVICE

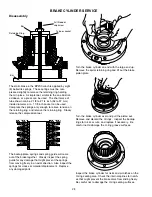

Disassembly

NOTE: The illustrations show the output carrier assem-

bly. Follow the same steps to service the primary carri-

er. The only difference is that the primary planet gears

have only one bearing, and no bearing spacer.

Drive the three (3) spiral pins into the center of the plan-

et gear shafts.

Remove one (1) planet gear shaft, two (2) thrust wash-

ers, two (2) roller bearings and one (1) planet gear from

each of three (3) locations in the carrier.

NOTE: The primary carrier gears have only one roller

bearing, and no spacer.

After all planet gears are removed, remove the thrust

washer from the carrier.

Use a punch to drive the spirol pins out of the planet

gear shafts. The same surface and material conditions

that are detrimental to the life of the bearings and thrust

washers also apply to the contact areas on the shafts

and carrier.

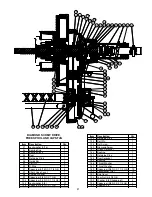

Thoroughly clean and inspect all planet carrier parts. If

the bearing rollers show any sign of spalling, corrosion,

discoloration, material displacement or abnormal wear,

the bearing should be replaced. Likewise, the cage

should be inspected for unusual wear or deformation,

particularly the cage bars. If there is any damage that

will impair the cage’s ability to separate, retain and

guide the rollers properly, the bearing should be

replaced. The thrust washer contact areas should be

free from any surface irregularities that cause excessive

abrasion or friction. The gears should be inspected for

abnormal wear or pitting. Replace if necessary.

Содержание Braden BP200

Страница 46: ......