WIRE ROPE INSTALLATION

6

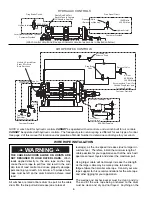

AIR OPERATED CONTROLS

Increasing PSI

Reduces Drag

Drag Brake

Valve

Nichols 2 Speed Motor

Brake Effective in

Both Directions

300 greater than return PSI

2500 PSI Max.

Two Speed

Shift Valve

(Manual or Solenoid)

30 GPM @

2500 PSI

Customer Provided

Freespool Valve

Air Inlet

75 PSI Min.

125 PSI Max.

Recommended Circuit For

Variable Drag Brake and

Freespool Function

Customer Provided

Freespool Indicater Circuit

Black

Green

Red

Power Source

12 VDC

Green

Red

Blue

Yellow

To Freespool

Solenoid Valve

BRADEN Supplied

HYDRAULIC CONTROLS

Drag Brake Circuit

500 PSI Max.

Hydraulic Inlet

Lever Operated Master Cylinder

Customer Provided

Route Rod End Port

Back to Tank to Contain

Oil Should a Seal Fail

Freespool Valve

(Solenoid or Manual)

Free Spool Circuit

Hydraulic Inlet

150 PSI Min.

250 PSI Max.

Customer Provided

(Winch control circuit and Freespool indicator circuit are same as in illustration below)

150 PSI Min

250 PSI Max

90 PSI Min

150 PSI Max

To Freespool

Solenoid Valve

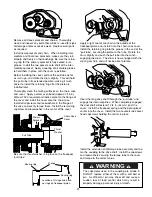

THE CABLE ANCHORS ALONE ON HOISTS ARE

NOT DESIGNED TO HOLD RATED LOADS.

Winch

loads applied directly to the wire rope anchor may

cause the wire rope to pull free and result in the sud-

den loss of load control and cause property damage,

personal injury or death. A minimum of 3 wraps of wire

rope must be left on the drum barrel to achieve rated

load.

CAUTION

WARNING

!

!

All winches are rated at bare drum line pull. As the cable

drum fills, the line pull will decrease (due to loss of

leverage), as the line speed increases (due to larger cir-

cumference). Therefore, install the minimum length of

cable possible for your application so that the winch will

operate on lower layers and deliver the maximum pull.

Using larger cable will not always increase the strength

as the larger cable may be more prone to bending

fatigue failure than smaller wire rope. Consult your wire

rope supplier for his recommendations for the wire rope

and other rigging for your application.

The wedge and anchor pocket must be clean and dry.

The end of the wire rope being anchored to the drum

must be clean and dry and not frayed. Anything on the

NOTE: A winch built for hydraulic controls

CANNOT

be operated with air controls, and a winch built for air controls

CANNOT

be operated with hydraulic controls. The freespool piston return spring is different for each type of control.

See page 2 of this manual for location and explanation of Model Number to determine control type for your winch.

Freespool Indicator Circuit

Содержание Braden BP200

Страница 46: ......