25

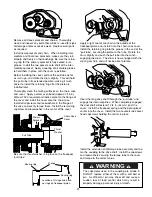

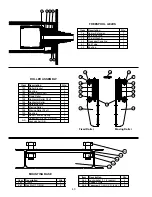

SERVICING THE WINCH GEAR TRAIN, BRAKE AND DRUM

Drain the oil from the winch drum and chain case as

described in “PREVENTIVE MAINTENANCE”, on page

12. Remove the hydraulic hose from the brake valve

block and the two capscrews and lockwashers holding

the motor to the motor adapter. Remove and discard

the motor gasket.

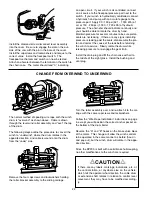

NOTE: If only the brake plates are being inspected

and/or serviced, they can be removed with the winch in

its normal position and without removing any parts from

the chain case end. If the winch is being completely

disassembled, proceed with all the following steps.

Remove the extension shaft, chain case and sprockets

as described in “LEVEL WIND DRIVE CONVERSION”

on page 19.

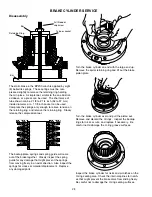

Provide adequate support and stand the winch on the

chain case end support bracket. Be sure to provide

clearance for the diamond screw and other parts

extending beyond the end of the support bracket.

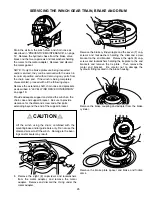

Remove the brake cylinder nipple and the seven (7) cap-

screws and lockwashers holding the diamond screw

bracket to the end bracket. Remove the eight (8) cap-

screws and lockwashers holding the tie plate to the end

brackets and remove the tie plate. Then remove the

motor end bracket. Be careful not to damage the

hydraulic fitting located in the brake housing.

8. Remove the eight (8) capscrews and lockwashers

from the motor adapter, and remove the motor

adapter. Remove and discard the O-ring under the

motor adapter.

Lift the winch using the drum, combined with the

mounting base and/or guide bars only. Do not use the

diamond screw to lift the winch. Damage to the bear-

ings and/or seals may result.

CAUTION

Remove the brake coupling and adapter from the brake

cylinder.

Remove the brake plate spacer and brake and friction

discs.

Содержание Braden BP200

Страница 46: ......