12. Install the brake clutch assembly.

NOTE:

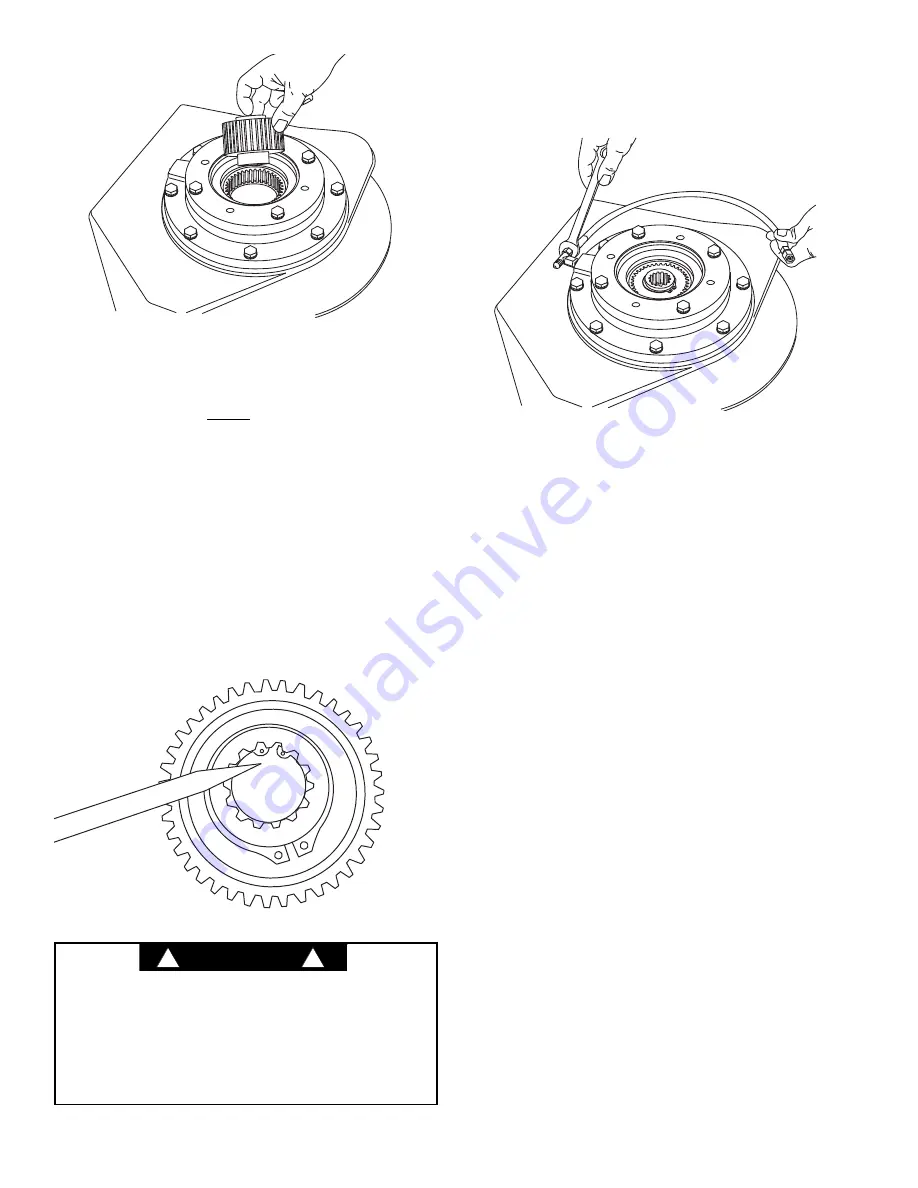

The snap ring installed in the bore of the inner

race is not centered in the splines. The long spline

engagement end

MUST

always install toward the

motor to permit proper positioning of the brake clutch

within the internal brake assembly.

When installed correctly, the inner race should turn

freely in the opposite direction the drum turns to pull

wire rope in. An easy way to check the rotation is to

hold the outer race in one hand, and rotate the inner

race from the motor side.

If the clutch free wheels in the wrong direction, disas-

semble the clutch and reverse the inner race. Refer

to "Brake Clutch Service” for additional information.

13. If the brake discs are misaligned, preventing the

installation of the clutch, then with a hand pump, apply

750-1000 psi to the brake release port. The brake

discs will move freely with the brake released

14. Install the hoses and fittings to the brake cylinder

release port.

15. Install a new O-ring on the motor pilot then lubricate

with petroleum jelly or gear oil.

16. Engage the motor shaft with the brake clutch inner

race and lower motor into place. Tighten capscrews

to recommended torque.

17. Install the hoses that connect the manifold and brake

valve to the brake cylinder.

18. After the hoist assembly is complete, check all cap-

screws and fittings to make certain they have been

tightened correctly.

Refill the hoist with the recommended oil listed under

“Preventive Maintenance”, and install the oil level

plug.

28

WARNIN G

Be certain the snap ring is seated in the groove in the

splined bore of the inner race. This snap ring will keep

the brake clutch assembly correctly positioned in the

center of the friction brake pack. Binding of the brake or

brake failure may occur if this snap ring is omitted.

CAUTION

WARNING

!

!

Содержание BRADEN Gearmatic BG6A

Страница 2: ......