CAP.2.

SPECIFICHE TECNICHE

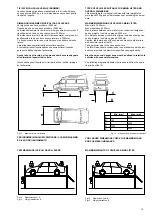

PORTATA: ................................................8000 kg (78400 N)

Alt. max. sollevamento auto ......................2000mm

Alt. min. supporti sollevamento .................190 mm

Interasse longitudinale colonne.................5920mm

Interasse trasversale colonne ...................3480mm

Larghezza libera tra colonne .....................3300mm

Larghezza pedane ...................................650 mm

Lunghezza pedane ...................................6200mm

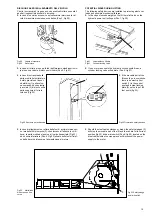

Tempo di salita . . . ...................................55 sec

Tempo di discesa . ...................................55 sec.

FUNE di sollevamento in acciaio, con le seguenti caratteristiche:

Diametro . . . . . . . . ...................................11 mm

Numero di fili . . . . . ...................................227

Resistenza dei fili . ...................................1960 N

Diametro primitivo pulegge .......................220 mm

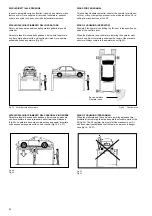

Rumorosità . . . . . . 70dB(A)/1m

PESO totale del sollevatore .....................circa 1820 Kg

Temperatura di funzionamento .................-10°C / + 50°C

Pressione di lavoro ....................................160 bar

Ambiente di lavoro: locale chiuso.

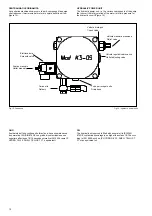

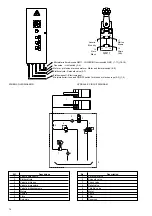

MOTORE ELETTRICO

Tipo . . . . . . . . . . . . C90

Potenza . . . . . . . . . 3 KW

Tensione

230-400V trif. +/-5%

Frequenza . . . . . . . 50 Hz

N° poli . . . . . . . . . . 4

Velocità . . . . . . . . . 1400 giri/1’

Forma costruttiva . B 14

Classe isolamento. F

Assorbimento . . . . 230V: 15A

. . . . . . . . . . . . . . . 400V: 8,7A

Il collegamento del motore deve

essere eseguito riferendosi agli

schemi elettrici allegati.Il senso

di rotazione del motore è sinistro

(antiorario) come indicato nella

targhetta applicata sul motore

stesso.

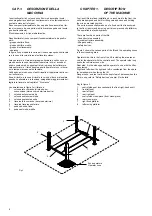

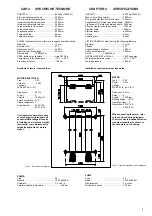

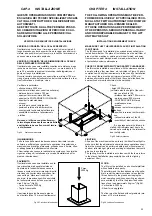

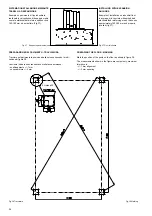

Fig.11 Dimensioni ed ingombri

POMPA

Tipo . . . . . . . . . . . . ...................................20

Modello . . . . . . . . . ...................................10A7,4X348N

Cilindrata . . . . . . . . ...................................7,4 cm3 /g

Taratura valvola di massima ...............................160 bar

CHAPTER 2

SPECIFICATIONS

CAPACITY: ...............................................8000 kg (78400 N)

Max. vehicle lifting height ..........................2000mm

Min. ground clearance of lift structure .......190 mm

Longitudinal C/C distance between posts . 5920mm

Transverse C/C distance between posts... 3480mm

Effective clearance between posts............ 3300mm

Platform width . . . . ................................... 650mm

Platform length . . . ...................................6200mm

Lift time . . . . . . . . . ..................................55 sec

Lowering time . . . . ..................................55 sec

LIFTING CABLES in steel, having the following features:

Diameter . . . . . . . . ...................................11 mm

Strands . . . . . . . . . ...................................227

Tensile strength of strand..........................1960 N

Pulley pitch diameter .................................220 mm

Noise . . . . . . . . . . . 70dB(A)/1m

OVERALL WEIGHT of lift unit ...................1820 kg approx.

Working temperature range.......................-10°C / + 50°C

Working pressure ......................................160 bar

Installation requirements: enclosed area.

MOTOR

Type ...........C90

Power .........3 kW

Voltage

230-400V th.-ph. +/-5%

Frequency ..50 Hz

Poles ..........4

Speed.........1400 rpm

Building shape .....B 14

Insulation class ....F

Absorption ..230V: 15A

...................400V: 8,7A

When connecting the motor refer

to the enclosed wiring diagrams.

The motor has left-handed rotation

(counter-clockwise) as shown on

the data plate on the casing.

Fig.11 Overall dimensions and clearances

PUMP

Type . . . . . . . . . . . ...................................20

Model . . . . . . . . . . ...................................10A7,4X348N

Displacement . . . . ...................................7,4 cc/rev.

Relief valve set-up ...................................160 bar

9

Содержание 528C

Страница 1: ...I PONTE SOLLEVATORE A 4 COLONNE GB 4 POST LIFT 528C...

Страница 2: ......

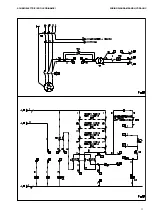

Страница 13: ...SCHEMI ELETTRICI ED OLEODINAMICI WIRING DIAGRAMS AND HYDRAULIC 11...

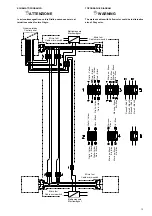

Страница 28: ...Fig 40 Fig 40 26 B K X K X Fune K Colonne 1 3 Fune X Colonne 2 4 Cable K Posts 1 3 Cable X Posts 2 4...

Страница 42: ...COLONNE POSTS S ULEN COLONNES COLUMNAS...

Страница 43: ...TRAVERSE CROSSBEAMS TRAVERSE TRAVERSES TRAVERSA OS...

Страница 44: ...PEDANE PLATFORMS FAHRSCHIENE CHEMINS DE ROULEMENT PLATAFORMAS...

Страница 45: ...CILINDRO CYLINDER ZYLINDER V RIN CILINDRO...

Страница 47: ...QUADRO ELETTRICO TRIFASE CONTROL PANEL SCHALTTAFEL DREHSTROM COFFRET LECTRIQUE CUADRO ELECTRICO...