4430 Planer

OLIVERMACHINERY.NET

39

|

Page

Instructions for Maintenance and Adjustments

WARNING

Disconnect the machine from the power source before any maintenance work is

performed. After servicing the planer, remove all wrenches and tools before

restarting the machine. Failure to comply can cause serious injury!

Remove Planer Top Cover

This allows you to service the cutterhead, chip

deflector, and chip breaker.

1.

Disconnect the planer from the power

source!!

2.

Remove dust hood.

3.

Remove the planer cover by removing the

four cap screws from the top of the planer.

Adjust Chip Deflector Clearance

The chip deflector was pre-installed in the

factory and should not require adjustments

initially. If the gap between the chip deflector

and cutterhead goes beyond the

1/16”

-

1/8”

tolerance, adjustment is needed.

1.

Disconnect the planer from the power

source!!

2.

Remove dust hood and top cover.

3.

Loosen the three bolts that secure the chip

deflector.

4.

Adjust the distance between the chip

deflector and the cutterhead. The entire

edge of the chip deflector should be no less

tha

n 1/16” away from the closest point of

the cutter head, but no more than 1/8”.

5.

Re-tighten the bolts to secure the chip

deflector, then reinstall the top cover and

dust hood.

6.

Remove all wrenches and tools before

restarting the planer.

Содержание 4430.201 M-4430

Страница 2: ......

Страница 10: ...10 Page Oliver Machinery 4430 Planer Identification...

Страница 11: ...4430 Planer OLIVERMACHINERY NET 11 Page...

Страница 12: ...12 Page Oliver Machinery 4430 Planer...

Страница 38: ...38 Page Oliver Machinery 4430 Planer Figure 1 Figure 2 Figure 3 Figure 4 Figure 5 Figure 6...

Страница 50: ...50 Page Oliver Machinery 4430 Planer Wiring Diagram...

Страница 51: ...4430 Planer OLIVERMACHINERY NET 51 Page Parts List Table Assembly...

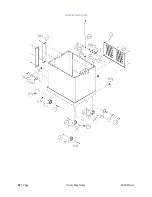

Страница 52: ...52 Page Oliver Machinery 4430 Planer Cabinet Assembly...

Страница 53: ...4430 Planer OLIVERMACHINERY NET 53 Page Motor Mount Assembly...

Страница 54: ...54 Page Oliver Machinery 4430 Planer Headstock Assembly...

Страница 55: ...4430 Planer OLIVERMACHINERY NET 55 Page Gearbox Assembly Cover and Dust Hood Assembly...

Страница 62: ...62 Page Oliver Machinery 4430 Planer Maintenance Record Date Task Operator...

Страница 63: ...4430 Planer OLIVERMACHINERY NET 63 Page Notes...