Section 6: CALIBRATION PROCEDURE

Do not attempt to recalibrate unless

you are absolutely sure that the con-

trol needs to be recalibrated and that the proper

equipment is available. Once this is preformed, all

other calibration information will be lost!

WARNING!

Equipment Needed:

1) Standard millivolt power source range 0-

100mV, accuracy ±0.01%

2) Standard voltage power source range 0-10V,

accuracy ±0.01%

3) Standard current power source range 0-20mA,

accuracy ±0.01%

4) Standard ohm source range 0-300 ohm,

accuracy ±0.01%

5) Standard thermometer range 0-50.0°C,

accuracy ±0.2°C

6) A cooling fan may be needed to keep

equipment cool

7) Thermocouple simulator

8) Pushbutton switch

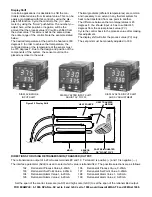

Calibration Set-up:

1) Select Input type to J T/C, UNIT = C,

RESO = 1dp

2) Turn power OFF

3) Disconnect all wiring

4) Connect wiring as shown below:

5) A fan should be used to keep the cold junction

compensator cool. (Lower PCB rear)

+

–

12

13

14

15

16

V

V

–

+

ETR-9200

40mV

200 ohm

10V

20mA

SWI

PTA

TC-/MV- COM+

MA-

V-

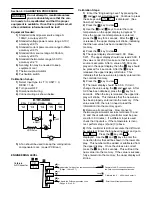

Calibrate

A-D Converter

or

or

or

Adjusts the Cold junction compensation code.

(Range -19.9 to 42.7)

Adjusts the Drift compensation code.

(Range -6.6 to 6.6)

Long

Long

Long

Calibrate the A-D converter and enter

the Cold-Junction compensation code.

Calibrate the 0

4-20mA and enter it.

Enter the drift compensation code

Calibration Steps:

1) Enter the “Engineering Level” by pressing the

and keys simultaneously. Continue to press

these keys until is displayed. (See

flow chart below.)

2) Press the key to view .

3) Use the and keys to enter the room

temperature on the upper display in degrees °C.

Once the proper room temperature is entered,

press the key for 4 seconds. After the key

is released, the upper display will strobe, indicating

that the new value has been loaded into the

memory.

4) Press the key to view .

5) The upper display should read 0.00. Close

SW1. The upper display should now read 20.00. If

the value is not 20.00, make sure that the current

source is accurate. After a value of 20.00 is dis-

played in the upper display, then the key should

be pressed for 4 seconds. After the key is

released, the upper display will strobe. This

indicates that the new value is properly entered into

the controller memory.

6) Press the key to view .

7) The lower display should be 0.00. If it isn’t,

change the value using the and keys. After

0.00 has been obtained, press the key for 4

seconds. When the key is released, the upper dis-

play will strobe. This indicates that the new value

has been properly entered into the memory. If the

value was 0.00, there is no need to load the

information into the memory again.

8) Remove all connections. Now connect a

thermocouple simulator accross terminals 13 and

14 and check calibration (controller must be pow-

ered for 30 minutes). If a different input is used,

check that input also. If the temperature is incor-

rect, perform steps (2) and (3) above.

9) If the controller is still not accurate the drift must

be adjusted. Enter the Engineering Level and go to

. Press the key until is

displayed. Use the and keys to enter the

correction factor that will be shown in the lower dis-

play. This number will be added or subtracted from

the upper display. Once the values are correct,

press the key for 4 seconds. This will load the

new value into the memory. If the value is success-

fully entered into the memory, the upper display will

strobe.

ENGINEERING LEVEL