Initial Operation:

When the control has been wired you can apply power.

The display should indicate the model number, software

version and LED lamp illumination test. The

temperature (or other process variable) as measured at

the sensor should be indicated by the PV display. The

thermocouple is wired in reverse if the indicated

temperature decreases as the temperature at the

thermocouple increases. While making initial settings

to configure the control, the set point should be lowered

to a value (eg. 30°F) to assure the heaters will not be

energized. This will allow time to make any adjust-

ments of the parameters in the operators or engineering

level.

During this initial set-up, alarm points and other settings

can be made. The low limit and high limit range set-

tings (Lo.SC) and (hi.SC) should be adjusted to your

process. This sets the range (span) of the control. The

set point cannot be adjusted out of this range.

Generally, for plastics processing and packaging, a

span of 0 - 800°F is common. If oils are used, a lower

span such as 0 -300°F should be entered.

When the configuration settings have been made, you

can return to the PV/SV level. Adjust the required

process set point. The red “out” lamp should illuminate,

indicating the heaters have been powered.

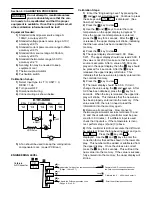

Autotuning:

The autotune function “teaches” the controller the main

characteristics of the process. It “learns” by cycling the

output on and off. The process will oscillate around the

set point during autotuning. Note the diagram below:

Adjust the set point to a lower value if overshoot

beyond the normal process value may cause damage.

The results are measured and used to calculate the

optimum PID values. It should not have to be repeated

on the same process. The autotune function starts by

depressing the and keys for 4 seconds; then

release. The process value display will flash on and off

indicating the control is in the autotune mode. No other

adjustments can be made to the system while the con-

trol is autotuning. The control will finish autotuning by

itself and the correct PID values will be entered into the

control’s memory.

Autotuning will not function if the control has been con-

figured from PID to ON-OFF. For electric heating PID is

usually recommended.

Autotuning may not give satisfactory results and hold a

close temperature on all applications. If this occurs,

you can change the PID values manually using the

three charts in Figure 5.2 on the top of the next page

for a guide. It is recommended to change only one

parameter at a time, so the results of that change can

be clearly noted.

Adjusting PID Parameters:

The PID parameters can be reviewed by operating the

scroll key and noting whether the values are reasonable

or not. Examine the controller’s result. Modify the PID

values until the control quality is acceptable.

ON-OFF Control:

On-off control action is recommended when continuous

cycling of the load cannot be used. Examples are

mechanical solenoids, large contactors and valves. For

on-off control, set the following parameters to zero:

proportional band; integral; derivative and offset (oFSE).

The hysteresis (hySE) adjustment is now used to set

the deadband. The larger the hysteresis is set, the

larger the deadband will be. A large deadband will

cause the contactor (or other device) to switch less

often, but the process will oscillate farther from the set

point. This setting is measured in degrees.

Initial Period

Process Oscillates

Verifying period

PID Control

Smarter Logic + PID

Set Point

Value

PB, TI, TD

Obtained

Autotune Finished

oFSE Value

Obtained

TEMPERATURE

TIME

Process

Value

Figure 5.1 Autotuning