www.nitronic.ch

-

44 -

Nitronic AG

Mattenstrasse 11

CH – 2555 Bruegg

Tel.

+41 32 373 7070

Switzerland

Fax

+41 32 373 70

75

Cleaning and Inspection

The cleaning intervals primarily depend on the material to be processed and the quantity of strip-

ping slugs produced. The

cleaning and inspection activities

listed below should be performed

daily or as needed.

Turn OFF the machine and disconnect the mains cable.

Cleaning of the work space

Do not use compressed air for cleaning purposes!

Otherwise, smallest pieces

of strands can enter the stripping head.

•

Remove safety cover (2) (Fig. 2, page 11).

•

Using a cleaning brush remove any stripping debris from the processing space.

•

Repeat this procedure DAILY or as needed.

Cleaning the stripping blades and centralizers

•

Move (tension) blade holders (11) inwards and move the cen-

tralizers (13) to the outside (Fig. 40).

•

Remove dirt using the cleaning brush supplied.

•

Inspection: The centralizers (13) must move freely. If their

movement/play is impeded by dirt deposits a proper stripping

efficiency cannot be assured.

•

Inspection: Condition of the stripping blades, replace if nec-

essary, see page 28.

Cleaning of the grippers

The clamping surfaces of the grippers must be clean to make sure wires can be held in place se-

curely.

•

Clean the spaces and corrugations at the grippers with a brush.

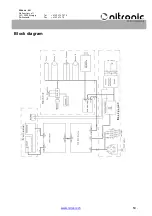

Fig. 40. Move blade holders in-

wards