www.nitronic.ch

-

43 -

Nitronic AG

Mattenstrasse 11

CH – 2555 Bruegg

Tel.

+41 32 373 7070

Switzerland

Fax

+41 32 373 70

75

•

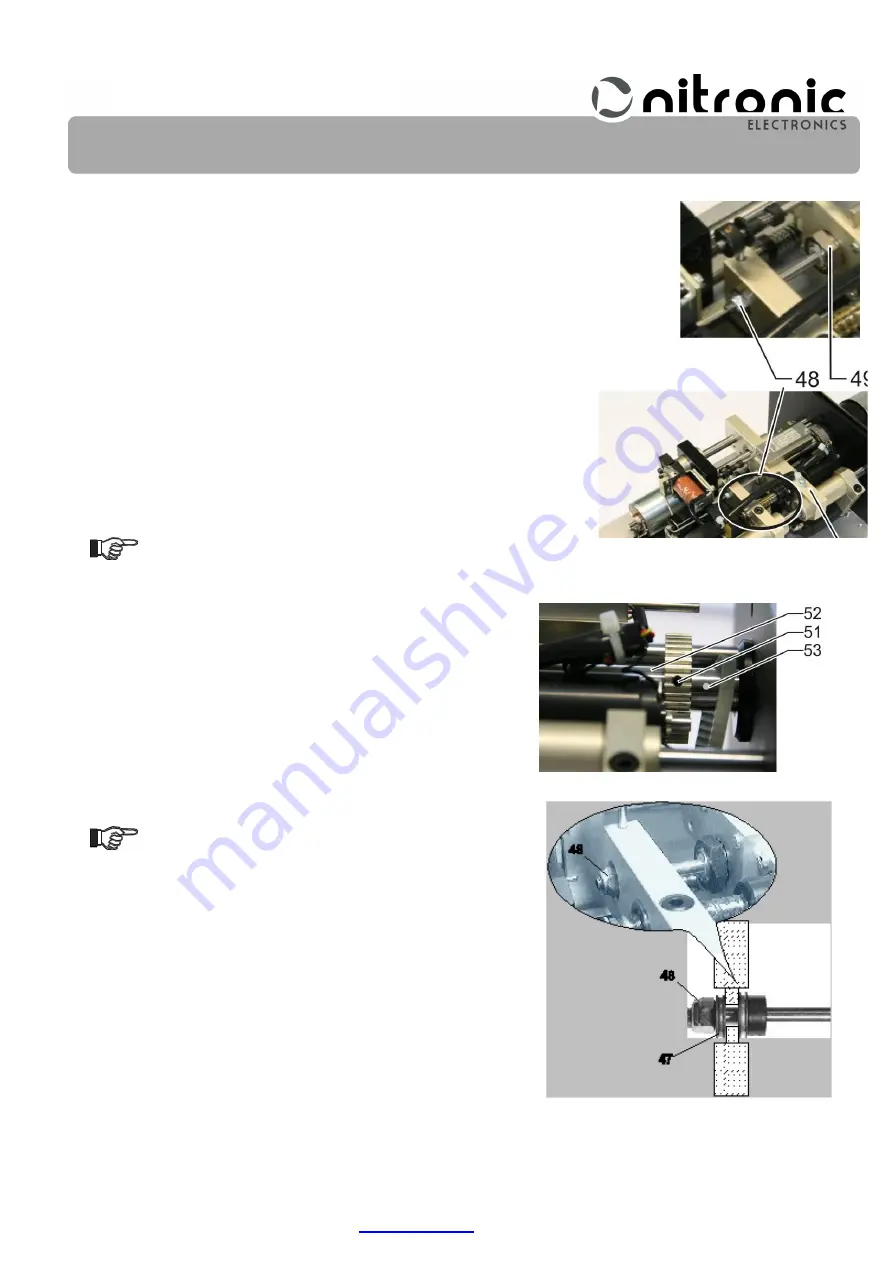

Unscrew and remove locknut (48) (Fig. 37).

•

Unscrew nut (49) of the stripping shaft (Fig. 37).

If an

L

is punched into the motor carrier (50) the nut (49) has a left-hand thread

(Fig. 37).

•

Loosen the set screw (51) by approx. 4 turns and pull the

stripping shaft (52) out of the machine (Fig. 38).

•

Install a new belt and mount the stripping shaft (52) in

reverse order (Fig. 38).

When tightening locknut (48)

make sure minimum clearance

exists between the nut and the

counter-washer (47) of the bear-

ing (Fig. 39).

Afterwards, the trigger device and grippers must be adjusted

again (page 37, and 40).

Fig. 38. Dismantle stripping shaft

Fig. 39. Axial bearing clearance