2018.11 / m

17

Electric Power Generation

Installation and maintenance

LSA 40

Low Voltage Alternators - 4 pole

4455 en -

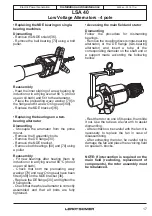

• Replacing the NDE bearing on single-

bearing machines

Dismantling

- Remove the NDE shield [36].

- Remove the ball bearing [70] using a bolt

puller.

Reassembly

- Heat the inner slipring of a new bearing by

induction or in a drying oven at 80 °C (do not

use an oil bath) and fit it to the alternator.

- Place the preloading wavy washer [79] in

the flange and fit a new O ring seal [349].

- Replace the NDE bracket [36].

• Replacing the bearings on a two-

bearing alternator

Dismantling

- Uncouple the alternator from the prime

mover.

- Remove the 8 assembly bolts.

- Remove the DE flange [30].

- Remove the NDE bracket.

- Remove both bearings [60] and [70] using

a puller.

Reassembly

- Fit new bearings after heating them by

induction or in a drying oven at 80 °C (do not

use an oil bath).

- Check that both the preloading wavy

washer [79] and new O ring seal have been

fitted [349] on the NDE bracket [36].

- Replace the DE flange [30], and tighten the

8 fixing bolts.

- Check that the whole alternator is correctly

assembled and that all bolts are fully

tightened.

• Accessing the main field and stator

Dismantling

Follow the procedure for dismantling

bearings.

- Remove the coupling discs (single-bearing

alternator) or the DE flange (two-bearing

alternator) and insert a tube of the

corresponding diameter on the shaft end or

a support made according the following

bellow.

- Rest the rotor on one of its poles, then slide

it out. Use the tube as a lever arm to assist

dismantling.

- After extraction, be careful with the fan. It is

necessary to replace the fan in case of

disassembling.

- After extracting the rotor, be careful not to

damage the fan and place the revolving field

on special V-blocks.

NOTE: If intervention is required on the

main field (rewinding, replacement of

components), the rotor assembly must

be rebalanced.