2018.11 / m

15

Electric Power Generation

Installation and maintenance

LSA 40

Low Voltage Alternators - 4 pole

4455 en -

• Checking the winding

You can check the winding insulation by

performing a high voltage test. In this case,

you must disconnect all AVR wires.

WARNING

Damage caused to the AVR in such

conditions is not covered by our

warranty.

• Checking the windings and rotating

diodes using separate excitation

During this procedure, make sure that

the alternator is disconnected from any

external load and inspect the terminal

box to check that the connections are

fully tightened.

1) Stop the unit, disconnect and isolate the

AVR wires.

2) There are two ways of creating an

assembly with separate excitation.

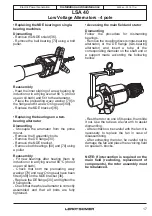

Assembly A:

Connect a 12 V battery in

series with a rheostat of approximately

50 ohms - 300 W and a diode on both exciter

field wires (5+) and (6-).

6 -

5 +

1A diode

12V battery

Rh. 50 -300W

-

+

ASSEMBLY A

Field

Assembly B:

Connect a “Variac” variable

power supply and a diode bridge on both

exciter field wires (5+) and (6-).

Both these systems should have

characteristics which are compatible with

the field excitation power of the machine

(see the nameplate).

3) Run the unit at its rated speed.

4) Gradually increase the exciter field

current by adjusting the rheostat or the

variac and measure the output voltages on

L1 - L2 - L3, checking the excitation voltage

and current at no load (see the machine

nameplate or ask for the factory test report).

When the output voltage is at its rated value

and balanced within 1% for the rated

excitation level, the machine is in good

working order. The fault therefore comes

from the AVR or its associated wiring (ie.

sensing, auxiliary windings).

1A diode

-

+

6 -

5 +

Variac

AC

220V

DC

12V

50

60

70

80

90

100

40

30

20

10

0

ASSEMBLY B

Field

• Checking the diode bridge

A diode in good working order should allow

the current to flow only in the anode-to-

cathode direction.

+R

+R

+

-

-W

-W

IN

IN

IN

IN

A n o d e

C a t h o d e