2018.11 / m

16

Electric Power Generation

Installation and maintenance

LSA 40

Low Voltage Alternators - 4 pole

4455 en -

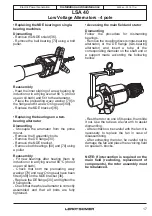

4.6 - Dismantling, reassembly

During the warranty period, this

operation should only be carried out in

an approved workshop or in our factory,

otherwise the warranty

may be invalidated.

Whilst being handled, the machine

should remain horizontal (rotor not

locked in position). Check how much the

alternator weighs before choosing the

lifting method.

• Tools required

To fully dismantle the machine, we

recommend using the tools listed below:

- 1 ratchet s extension

- 1 torque wrench

- 1 set of flat spanners: 8 mm, 10 mm, 12 mm

- 1 socket set: 8, 10, 13 mm

- 1 socket TORX bit T20, T30

- 1 puller (eg. Facom: U35, U32/350)

• Bolt tightening torque

See section 5.3.

The bolts for fixing the feet on the

housing and immobilising the stator

must not be removed (bolt of the stator

lower).

• Access to connections and the

regulation system

The terminals and AVR are accessed

directly by removing the terminal box lid

(41).

• Accessing, checking and replacing the

diode bridge

Dismantling

- Remove the terminal box lid [41].

- Cut the fixing clamps of the exciter cables,

disconnect E+, E- from the exciter.

- Remove the 4 nuts on the tie rods.

- Remove the NDE shield [36] using a puller:

eg. U.32 - 350 (Facom).

- Unsolder the connections.

- Check the bridge using an ohmmeter or a

battery lamp.

Reassembly

- Replace the bridges, respecting the

polarity.

- Resolder the connections.

- Fit a new O ring seal in the shield.

- Refit the NDE shield and pass the bundle

of wires between the top bars of the shield.

- Replace the fixing clamps on the cables.

- Replace the terminal box lid [48].

WARNING

Rotor

NDE shield

M8 threaded rod