2018.11 / m

13

Electric Power Generation

Installation and maintenance

LSA 40

Low Voltage Alternators - 4 pole

4455 en -

4.4 - Mechanical defects

Fault

Action

Bearing

Excessive overheating of one or

both bearings

(bearing temperature 80°C above

the ambient temperature)

- If the bearing has turned blue or if the grease has turned

black, change the bearing.

- Bearing not fully locked (abnormal play in the bearing cage)

- End shields incorrectly aligned

Abnormal

temperature

Excessive overheating of

alternator frame (more than

40° C above the ambient

temperature)

- Air flow (inlet-outlet) partially clogged or hot air is being

recycled from the alternator or engine

- Alternator operating at too high a voltage (>105% of Un on

load)

- Alternator overloaded

Vibrations

Too much vibration

- Misalignment (coupling)

- Defective mounting or play in coupling

- Rotor balancing fault (Engine - Alternator)

Excessive vibration and humming

noise coming from the machine

- Phase imbalance

- Stator short-circuit

Abnormal

noise

Alternator damaged by a

significant impact, followed by

humming and vibration

- System short-circuit

- Misparalleling

Possible consequences

- Broken or damaged coupling

- Broken or bent shaft end

- Shifting and short-circuit of main field

- Fan fractured or coming loose on shaft

- Irreparable damage to rotating diodes/AVR, surge suppressor

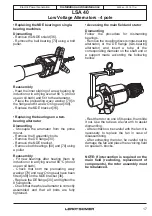

4.3 - Bearings

The bearings are permanently greased

Approximate life of the grease (depending on use) = 20,000

hours or 3 years.