16

5.3.3 As the figure shown, press the tire press roller and

the tire presser under the edge of the rim.

5.3.4Clockwise rotate the turntable to drive the rim.

The most important is to check the rim and tire

to prevent the explosive during re-inflation

process. Before installation, you should secure:

Tire and tire thread fiber not damaged. If you

find the damage, do not mount the tire

;

The rim without dent and warp by visual check.

Note that there is not any small scratch inside

the Alum alloy rim. These are dangerous,

especially while inflation.

Use the special grease to lubricate the bead for fear the bead

to be damaged and convenient to operate.

When lock the rim, do not place the hand under

the tire. The correct operation is to position the

tire at the center of the turntable.

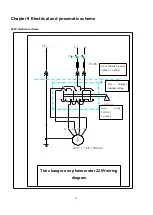

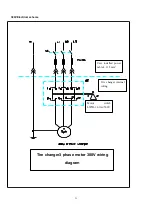

22inch turntable clamping range

:

10-20inch is the inside

clamping without washer;12-24inch is the outside clamping

While the column is tilting, you should make

sure that nobody is standing behind the column.

If the tire changer handle the same size of the

rim, it is no need to frequently lock or release

the lock of the tool arm. What you need to do is

only to tilt back and forward the column and

Содержание TC-1300

Страница 1: ...3456789 C61CN...

Страница 36: ...35...