40

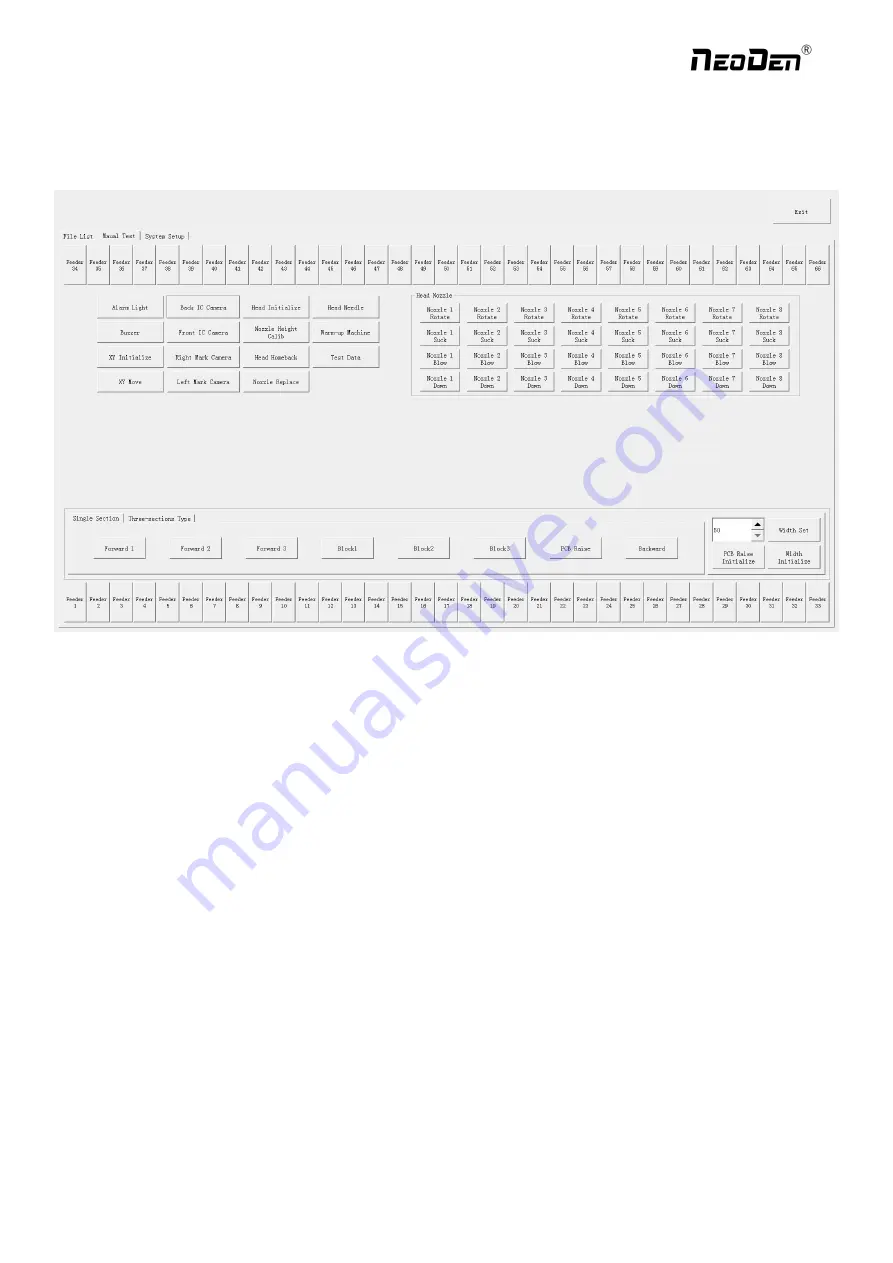

9. Manual Test

This interface is used to test each part’s function.

1.Feeder No.1-No.66: after loading tape reel on feeder, click the feeder to test its feeding function.

2.Alarm light: click it to test if the light could work correctly, the color should change from red, green to yellow by

sequence.

3.Buzzer: click it to test if it works

4.XY initialize: click to have XY back to zero

5.XY Move: click this button to enter vision interface, the movement mode are optional, use the crosshair to move the head.

6.Front IC Camera, Back IC Camera: click to test the photograph function.

7.Right Mark Camera,Left Mark Camera: click to test the photograph function.

8.Head initialize: head initialization can be executed before mounting

9.Nozzle Height Calib: click to calibrate 8 nozzles’ initial heights

10.Head Home back: click to move the head back to original left top position

11.Nozzle Replace: click to replace nozzles, the head will move to its position for easier replacement.

12.Head Nozzle: click to test rotation, suction, blow and moving down functions of nozzle NO.1-NO.8.

13.Width Set: after the initialization of rails width, enter the expected width, click Width Set, the rails be widened

accordingly

Zhejiang

NeoDen Technology Co.,Ltd.

Содержание K1830

Страница 6: ...1 3Working Area Structure Figure 3 Top view of main mounting area 6 Zhejiang NeoDen Technology Co Ltd ...

Страница 7: ...Figure 4 X axis Beam Figure 5 Main Placement Head Camera 7 Zhejiang NeoDen Technology Co Ltd ...

Страница 35: ...8 2 Component Positions Setup 35 Zhejiang NeoDen Technology Co Ltd ...

Страница 44: ...11 Structure and maintenance instruction 11 1 Feeder Brief Introduction 44 Zhejiang NeoDen Technology Co Ltd ...