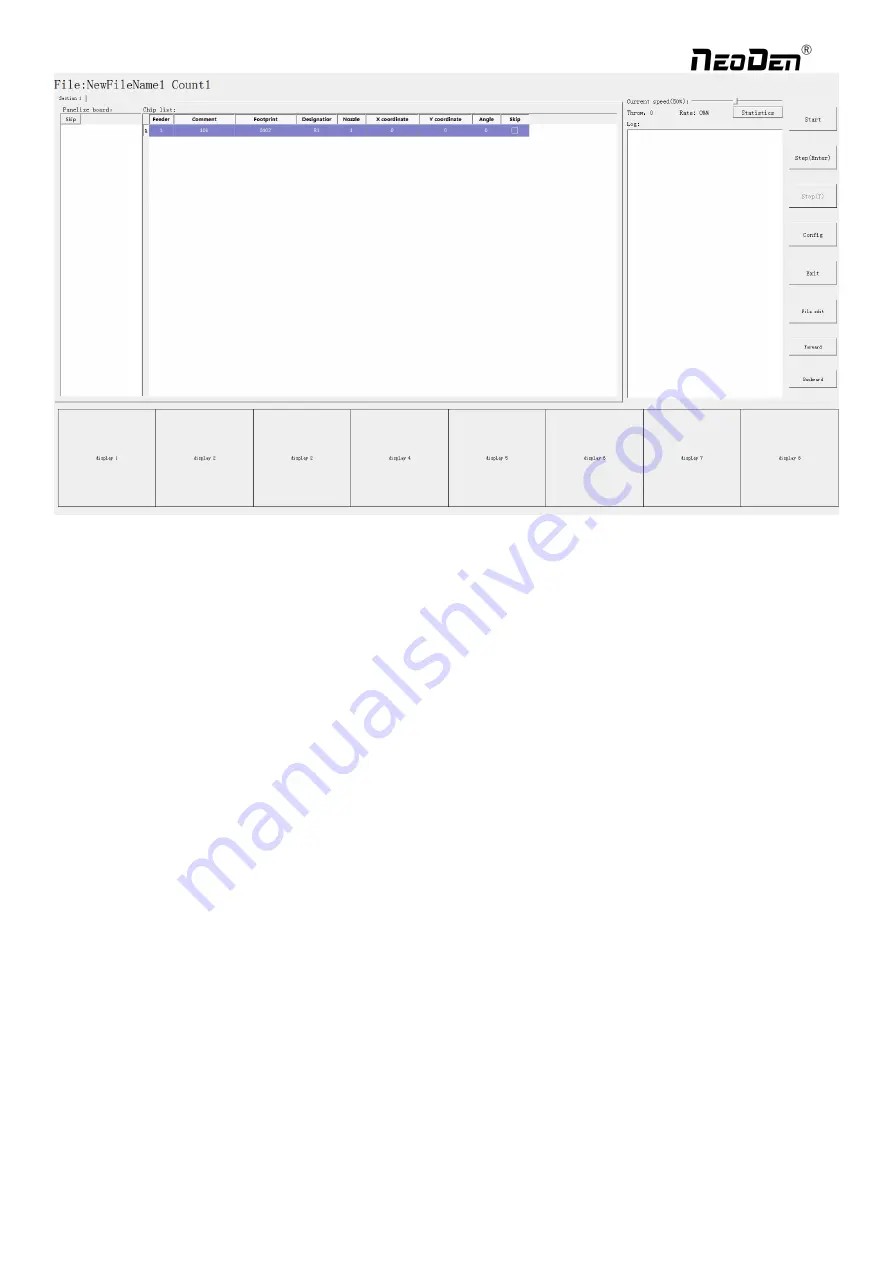

(1) Left part is detailed chip list, and following the highlight blue will get a real-time assembly situation;

(2) On right top is the current assembly speed, you can drag the scroll bar to change it and the max is 100%;

(3) Log will show some information like rate of throw component , current average speed and how many pieces

components have been assembled under the current file.

(4) Throw and Rate will make a statistics for threw components and you can also check each feeder’s component pick

failure rate then get which kind of component is easily pick failure, find solution to solve it.

(5) The bottom side 8 display windows are real-time feedback for component recognition.

(

6

)

Right side buttons introduction:

Start: Machine starts the current file’s assembly procedure.

Step: operation for each single assembly procedure.

Stop: Stop current assembly work.

Config: press this button, a detailed configuration will pop out as below

31

Zhejiang

NeoDen Technology Co.,Ltd.

Содержание K1830

Страница 6: ...1 3Working Area Structure Figure 3 Top view of main mounting area 6 Zhejiang NeoDen Technology Co Ltd ...

Страница 7: ...Figure 4 X axis Beam Figure 5 Main Placement Head Camera 7 Zhejiang NeoDen Technology Co Ltd ...

Страница 35: ...8 2 Component Positions Setup 35 Zhejiang NeoDen Technology Co Ltd ...

Страница 44: ...11 Structure and maintenance instruction 11 1 Feeder Brief Introduction 44 Zhejiang NeoDen Technology Co Ltd ...