Installation Guide

6/29/2023

14

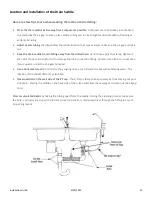

System Start

-

up

System Routine Maintenance

1.

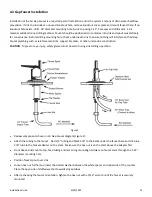

Check all connections and ensure they are secure.

2.

Turn on the feed water valve and check for leaks. (Turn off and correct leaks if any

occur)

3.

Close the valve on the storage tank and open the faucet until a steady fast drip or

stream of water flows. (The higher the selected membrane output, the more

water will flow) Water will be flowing to the drain as well. NOTE: The permeate

pump will not start working until the tank valve is opened and the tank reaches 7

psi.

4.

Once there is a steady fast drip or stream of water coming from the faucet, close

the faucet and wait five minutes to see if any leaks result on the system. The initial water from the system may be

slightly discolored. This is normal.

5.

If there are no leaks, open the storage tank valve and allow the system to fill. Most systems will be full within 2

-

3

hours depending on feed pressure, membrane output, and tank size. The system is full when the water to the

drain stops. Check for leaks with the system full and repair them accordingly. NOTE: When the system is first

turned on, water may intermittently "spurt" from the air gap opening on the side of air gap faucets. This is

common and should correct itself after the air is purged from the system. CAUTION: Ensure that the system is not

being fed with water above 75 PSI or damage to the system could occur.

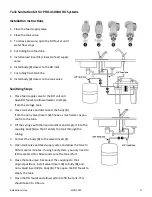

Periodic maintenance is needed on any water filtration appliance. The PRO

-

41000A is equipped with filters, a

membrane and a remineralization cartridge that will all require replacement from time to time to ensure that the

system continues to produce very high quality water.

Filter life is dependent on water usage as well as water conditions at the installation site. Carbon filters have a definite

exhaustion point. With a family of four with frequent use, the carbons and remineralizer should be replaced every six

months. A smaller family with less frequent use replacing them annually may be sufficient.

Membrane life will be extended if water is softened first. Non softened water will shorten replacement cycles but

typical membrane life is 2

-

3 years before needing to be replaced.

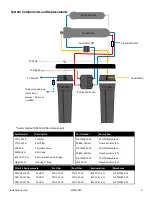

Filter Kit Replacements

Pre Filter

Post Filter

Remineralizer

Membrane

PRO

-

FK

-

1125A

25 GPD

CTO1

-

2510

CTO1

-

2510

IL2512

-

57

-

4Q

NP

-

TW1812

-

25

PRO

-

FK

-

1150A

50 GPD

CTO1

-

2510

CTO1

-

2510

IL2512

-

57

-

4Q

NP

-

TW1812

-

50

PRO

-

FK

-

1175A

75 GPD

CTO1

-

2510

CTO1

-

2510

IL2512

-

57

-

4Q

NP

-

TW1812

-

75

Содержание PRO-41000-A Series

Страница 20: ...Installation Guide 6 29 2023 20...