Installation Guide

6/29/2023

17

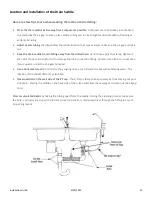

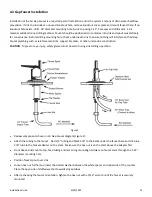

Tank Sanitation Kit for PRO

-

41000A RO Systems

1.

Close the feed supply valve

2.

Close the tank valve

3.

To relieve pressure, open the RO faucet until

water flow stops

4.

Cut tubing from feed line

5.

Install valved insert (

1

) closest to feed supply

valve

6.

Install body (

3

) closest to the RO inlet

7.

Cut tubing from tank line

8.

Install body (

4

) closest to the tank valve

1.

Close feed supply valve to the RO unit and

open RO faucet to allow all water to empty

from the storage tank.

2.

Close tank valve and disconnect the body (

4

)

from the non

-

valved insert (

2

). Shake as much water as you

can from the tube.

3.

Fill the syringe with the liquid sanitizer and empty it into the

coupling body (

4

) so that it enters the tank through the

tubing.

4.

Connect the body (

4

) to the valved insert (

1

).

5.

Open tank valve and feed supply valve and allow the tank to

fill for several minutes. If using Sani System, you only need to

let the water sit for 60 seconds once the tank is full.

6.

Close the tank valve. Reconnect the couplings to their

original positions, install valved insert (

1)

to body (

3)

, and

non

-

valved insert (

2)

to body (

4

). Then open the RO faucet to

empty the tank.

7.

Close the RO faucet and allow system to fill the tank. This

should take 3 to 4 hours.

Installation Instructions

Sanitizing Steps

Содержание PRO-41000-A Series

Страница 20: ...Installation Guide 6 29 2023 20...