Nelweld Operations and Service Manual

- 34 -

4.6.5 Time Display

The time display is used to display both the

desired time setting and the actual weld time. In

normal operating modes, the desired setting and

the actual weld time will be the same. When this

is the case, the display does not change during or

after a weld. However, if an error condition

occurs, the proper error code will be displayed on

the front panel display. This will typically

happen if a weld is aborted early.

Please note that when the current and time

are specified, the actual current and time

delivered during the weld cycle are

accurate to 3% of the specified value. Only when

the specified value is beyond this tolerance will

the current and/or time displays show a different

value.

4.6.6 Special Functions

The power source has several special functions as

described throughout this manual. These are

accessed by pressing the function, or “F”, key

followed by a numeric function code. When

accessing the special functions, the LED on the

function button will light and the upper display

will show “F” followed by the function code. All

of the preset button LED’s are OFF when in the

Special Function mode since they now act as a

keypad for entering the function codes. Scrolling

through the function codes can also be

accomplished by using the + and – keys to the

right of the function code display. The lower

display shows the current status or current value

of the selected function. When in the special

function mode, the selected machine output is

disabled. Note: as tabulated in Section 7.3, the

special function codes are sequentially numbered

using only digits 1 through 6.

4.6.7 Setpoints

The power source has six available setpoint

configurations. Each of these is assigned a time

and current setting for commonly welded stud

sizes. To select a setpoint, simply press key 1, 2,

3, 4, 5, or 6. When a setpoint is selected, its time

and current are displayed on the front panel, and

the LED on the selected preset key lights.

4.6.8 Setpoint Programming

Nelweld users are not restricted to pre-

programmed setpoints, but may save more usable

weld settings. To do so, first select the desired

time and current settings using the corresponding

+ and – keys. Then press and hold the desired

preset key for 4 seconds. When the green LED of

the preset button being pressed turns ON, the

selected

preset

has

been

successfully

programmed.

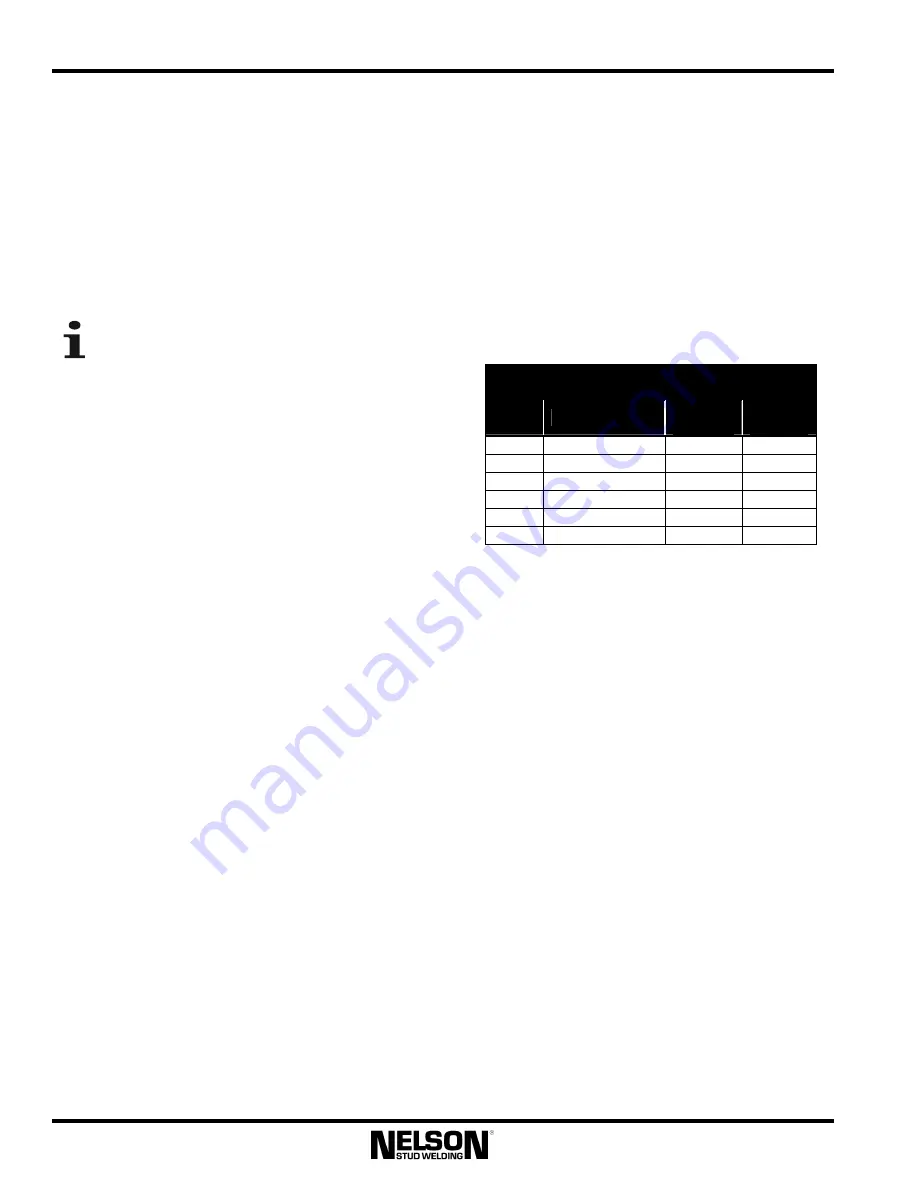

Factory Set Preset Weld Settings

Preset

Stud Size

Time

(seconds)

Current

(amps)

1

3/16”

(5mm)

0.150

300

2

1/4”

(6mm)

0.200

450

3

5/16”

(8mm)

0.250

550

4

3/8”

(10mm)

0.350

650

5

1/2”

(12mm)

0.550

850

6

5/8”

(16mm)

0.700

1200

4.6.9 Front Panel Lock

The front panel has a lockout feature that

prevents any changes from being made to the

front panel settings. The power source is shipped

with the lock disabled. Before using the lock

function, it must be enabled using special

function F45. The default combination for the

lock is 1-2-3-4.

To lock the control panel, press the LOCK key

followed by a 4-digit combination, as determined

by the operator.

Combinations of numbers that

are less than four (4) digits cannot be used to

lock the front panel.

Enter the combination into

memory by pressing the LOCK key again. This

will cause the LOCK key’s closed-lock-icon LED

to turn ON.

To unlock the control panel, press the LOCK key

followed by the previously entered combination,

and the LOCK key again. The LOCK key’s

open-lock-icon LED turns ON indicating that the

panel is now unlocked. In case a combination is

forgotten, a supervisory combination will work to

unlock the panel. The supervisory combination

Содержание Nelweld 4000

Страница 58: ...Nelweld Operations and Service Manual 58 7 5 Declaration of Conformity...

Страница 59: ...Nelweld Operations and Service Manual 59 8 0 Diagrams and Parts Lists 8 1 Front Section Not shown...

Страница 61: ...Nelweld Operations and Service Manual 61 8 2 Base and Side Cabinet Section...

Страница 65: ...Nelweld Operations and Service Manual 65 8 4 Rear Cabinet Section...

Страница 67: ...Nelweld Operations and Service Manual 67 8 5 Wiring Diagram...