Nelweld Operations and Service Manual

- 20 -

•

Burn through the base material.

In most arc welding processes the weld fillet

metal comes from the addition of filler metal

from a stick electrode or a spool of welding wire.

In stud welding a portion of the stud itself is the

source of the weld metal. The length of the stud

that is melted to develop the flash is called

burn-

off

, and is defined as the difference in length

between a welded stud and its original length.

The length reduction or burn-off is a very good

gauge of weld quality, since the burn-off is

determined by the weld settings of time, current,

lift, and plunge. Proper burn-off also indicates

that there was no bind or hang-up during the

plunge motion of the gun.

The most convenient method of checking

burn-off is to stand an unwelded stud

upside down (load end up) next to a

welded stud to compare the length difference.

After weld height can also be checked with a

sliding carpenter’s level/square tool. The

Stud

Burnoff Length

table shows typical burn-off

length reductions when welding to bare plate of

sufficient thickness.

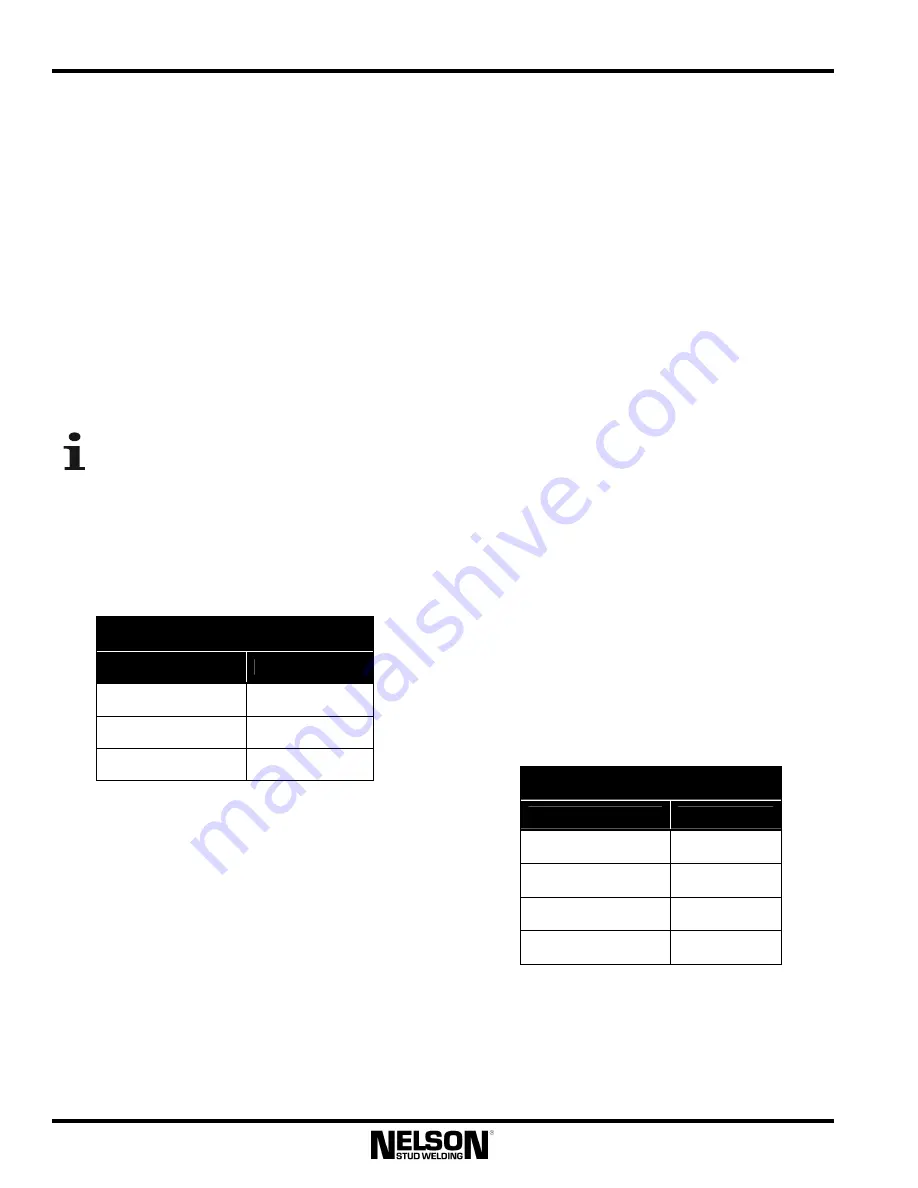

Stud Burn-Off Lengths

(not including flux load)

Stud Diameter

Length Reduction

3/16” through 1/2”

(5mm through 12mm)

1/8”

(3mm)

5/8” through 7/8”

(16mm through 22mm)

3/16”

(5mm)

1” and over

(25mm and over)

1/4”

(6mm)

2.7.5 Physical Weld Inspection

Two studs should be welded according to

qualified settings during pre-production testing.

Following satisfactory visual inspection, they are

bent 30º or torque tested in the case of threaded

studs. This procedure should also be followed if

there is any change of operator or any change in

equipment, position, settings, etc. Studs that are

bent may be straightened to the original axis.

Studs should not be heated during bending or

straightening without approval by the Engineer of

Record

. Torque testing is done to a proof load

level slightly lower than the nominal yield of the

stud so there is no permanent distortion of the

threads. Torque test proof load requirements are

found in AWS D1.1, D1.5, or D1.6. The test studs

may be used in production.

The stud welding operator is responsible for pre-

production set up and testing. The operator shall

weld two studs to a production weld plate or to a

piece of material similar to the weld plate in

material composition and within 25% of the

production weld plate thickness.

Inspections during production are also the

responsibility of the operator. Pre-production and

production inspection test results should be

recorded and approved by the welding supervisor.

Any

unsatisfactory

pre-production

and/or

production inspections and tests should be

brought to the welding supervisor’s attention and

corrections made, accompanied by additional

tests with fully satisfactory inspection and test

results before proceeding with further welding.

At regular intervals during production welding,

the studs welded after the last testing interval

should have the ceramic ferrules removed and

should be visually inspected. If the visual

inspection shows a full periphery weld flash,

without undercut, and satisfactory after weld

length, welding may continue. If the visual

inspection shows a lack of flash or insufficient

weld burn off, the questionable studs should be

marked and appropriate supervisory personnel

notified.

Minimum Weld Flash Size

Stud Diameter

Weld Flash Size

3/16” through 7/16”

(5mm through 11mm)

3/16”

(5mm)

1/2”

(12mm)

1/4”

(6mm)

5/8” through 7/8”

(16mm through 22mm)

5/16”

(8mm)

1” and over

(25mm and over)

3/8”

(10mm)

In accordance with codes, contract documents or

quality assurance inspection criteria, studs

without a full peripheral flash, but with a

satisfactory after weld length may be bent 15º in

the direction opposite the lack of flash, or

Содержание Nelweld 4000

Страница 58: ...Nelweld Operations and Service Manual 58 7 5 Declaration of Conformity...

Страница 59: ...Nelweld Operations and Service Manual 59 8 0 Diagrams and Parts Lists 8 1 Front Section Not shown...

Страница 61: ...Nelweld Operations and Service Manual 61 8 2 Base and Side Cabinet Section...

Страница 65: ...Nelweld Operations and Service Manual 65 8 4 Rear Cabinet Section...

Страница 67: ...Nelweld Operations and Service Manual 67 8 5 Wiring Diagram...