Blades

FIG. XX

BLADE SHARPENING (FIGURE YY)

Always check for blade sharpness before using; because dull blades greatly reduce

cutting effectiveness. Over time, the used blades will develop a back bevel. While re-

sharpening, blades will not recover entirely until the back bevel is completely leveled out.

NOTE: Thinner blades are easier to sharpen, but they also break easier.

•

Always wear gloves and safety glasses.

•

Grind blade using a 4” diameter disk with 120 or

fi

ner grit. Be careful not to catch

disk on edge or corner of blade.

•

Pass grinder along blade edge starting on one end and continuing in one direction

being careful to hold grinder at proper angle of blade. Grind until sharp.

•

While using a high quality

fi

ne tooth hand

fi

le, follow the same procedure as above.

•

Blades are sharp. Use extreme caution.

•

Have plenty of sharp blades on each job so on-the-job blade sharpening is elimi-

nated.

•

It is best to re-sharpen dull blades on proper bench or belt grinder in the shop, so

the blades are ready for the next job.

SELF-SCORING BLADE SHARPENING (FIGURE ZZ)

It is important to keep the “wings” on these self-scoring blades sharp. Use a

fi

le on the

edge. Sharpen the

fl

at part of the blade, the same way as described above.

CARBIDE TIPPED BLADE SHARPENING

To sharpen carbide tipped blades, a carbide grinding wheel is necessary, ie: silicon

carbide or green wheel.

DITCHING

CROSS ROOM DITCHING (FIGURE ZZ)

When removing hard to remove ceramic, Vct or vat, cross-room ditching will help to

make the removal easier. Using a blade 5 to 16 cm (2” to 6”) in width, make ditches 1’ to

2’ apart in the same direction the machine will be removing the goods (See Figure EE).

This “relieves” the pressure holding the tiles together. If ditching helps and the goods are

coming up easy, try using a wider blade to ditch with.

CHECKER BOARD DITCHING (FIGURE AA)

To make carpet removal and debris cleanup easier, checker board ditching is very help-

ful. Using as wide of a self-scoring blade as possible, make ditches 4’ to 6’ apart cross-

ways from the way the machine will be removing the goods (See Figure FF). Running

the machine crossways from the ditches will make smaller pieces of debris to be hauled

away. Instead of large gummy rolls of carpet, there are small squares that can be rolled,

palletized, put on a dolly or folded with the sticky side in. This makes removing the debris

easier and reduces the amount of debris.

Fax: 763-535-8255

25

1” BLADES (FIGURE XX)

Short pro

fi

le blades where a rigid blade application is needed. Thickness greatly reduces

breakage. Used for VCT & adhesive rescrape. Works well for parking deck coatings, epoxies

& elastomeric coatings.

7091

1” X 4” BLADE

.094

7092

1” X 8” BLADE

.094

7093

1” X 10” BLADE

.094

7094

1” X 12” BLADE

.094

PART# DESCRIPTION

THICKNESS (IN.)

FIG. YY

Front of Blade

Back Bevel

CROSS ROOM DITCHING

Ditch

2” to 6”

Blade

Tile

1’ to 2’

Strips

Figure ZZ

Run the machine the same direction

that the ditches are made

Carpet 4’ to 6’

apart

Use as

large of a

blade as

possible for

ditch

Figure AA

Run the machine crossways from the

directions that the ditches are made

CHECKER BOARD DITCHING

Self-Scoring Wing

Front of Blade

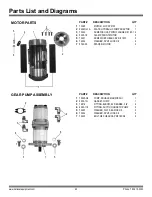

Содержание 5700-aus

Страница 1: ...Read Manual Before Operating Machine ALL DAY BATTERY RIDE ON SCRAPER INSTRUCTION MANUAL Rev B 401810...

Страница 2: ......

Страница 44: ...Parts List and Diagrams Fax 763 535 8255 info nationalequipment com 44 5700 BATTERY WIRING...

Страница 46: ...Parts List and Diagrams Fax 763 535 8255 info nationalequipment com 46 5700 MACHINE WIRING...