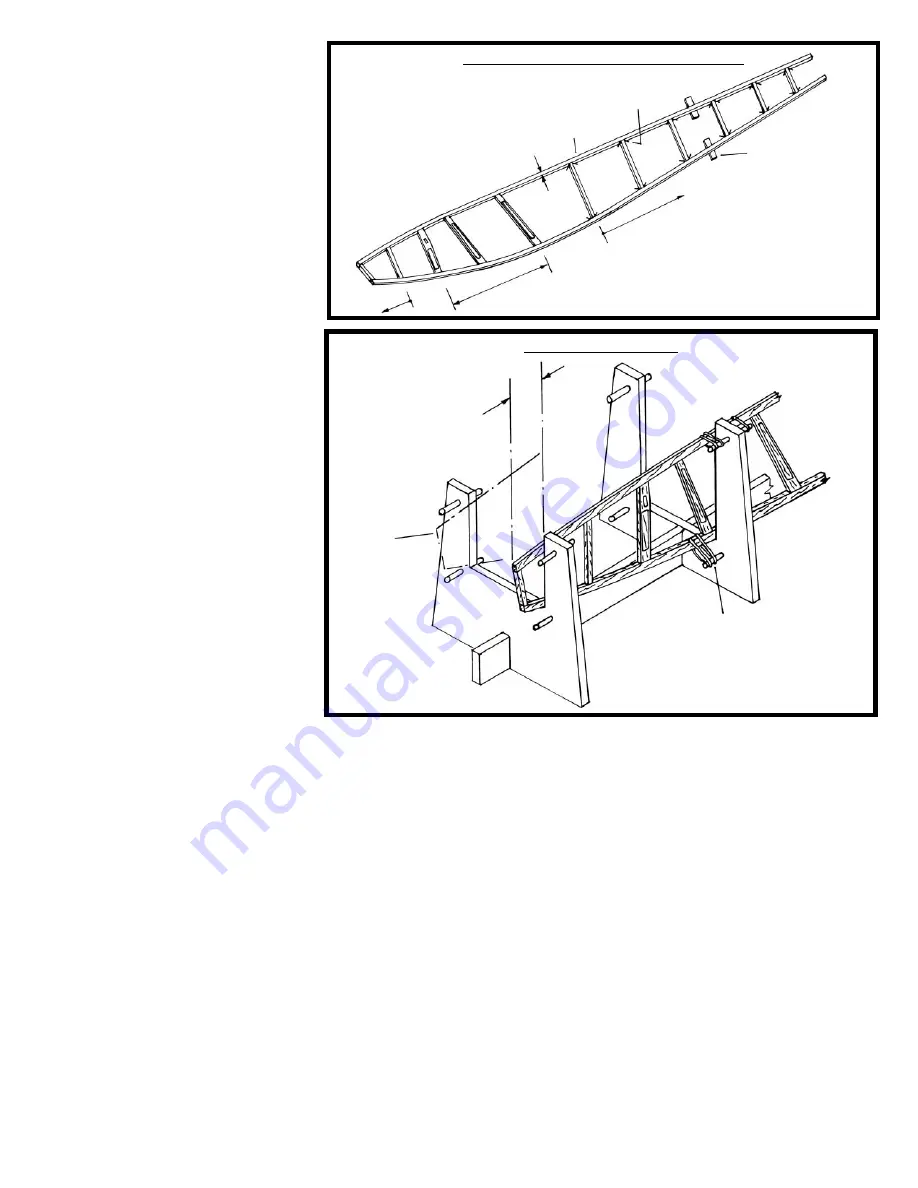

FIG. 3-5 SIDES IN JIG

1/2"

RIGHT

SIDE

RUBBER BANDS

AT EACH FORMER

17

(F27 through F32) and glue. These dowels

are used for rubber banding the fuselage

sides to the formers.

Fit each former in the slots in the center

piece. Check with a square to see if they are

perpendicular to the center piece and board.

Then glue them in place. Super glue will

work just fine here.

Figure 3-1

illustrates the

jig. Set the jig aside for now.

2. Building the Sides of the Fuselage

On the plan, starting at the nose, the side

vertical struts (and corresponding top and

bottom horizontal struts) are labeled Station

1 through 11. I will refer to these Stations in

the discussion.

The sides are to be built directly on the plan,

and both are identical. Build one side then the

other using the bottom plan on Sheet 3. This

view just shows the longerons, vertical struts,

and brace wire fittings that must be installed

along with the vertical struts. To avoid gluing

any parts to the plan, use some shims under

the longerons. Place these just to the side of

the vertical strut locations. Pin the 1/16" x

3/32" longerons over the plan. Since they are

raised a bit, make sure they are located direct-

ly over the longerons on the plan. The longer-

ons at the forward end have a rather sharp

curve, so it would be wise to heat-bend the

ends to conform to the curve. Heat-bending

will relieve some stress so the longerons won’t

spring apart and break glue joints.

Using the single plan for both sides requires

care in assembly. Remember that the right

side of the fuselage will be the inside you are

looking at. You want the other side, which will

be the outside of the fuselage, to look good

with no glue squeeze-out. An option, make a

reverse quick copy of the plan and you will

have two plans with the outside showing up.

Cut the vertical struts for both sides of the

fuselage at the same time, measuring lengths

from the plan.

At Station 1, there is a 1/16" wooden strut

that will later be covered by a photo-etched

plate (F15) that fits on the outside of the

longerons. On the real aircraft there is no

wooden strut at Station 1, but for the model

it aids assembly.

The strut at Station 2 is 1/16" square. Do not

add any fittings at this time. A special fitting

strut clip will be added later.

The three large struts at Station 3, 4, and 5 sup-

porting the center section wing struts and rear

end of the engine bearers on the real aircraft

are heavy struts mortised out along the center

on both sides. Cut these struts from stripwood.

For the model, make the mortise using a hobby

blade to cut the depth and a small chisel to hol-

low out the mortise

(Figure 3-2)

.

The rear struts at Station 6 through 11 must

be prefitted with a photo-etched copper two-

eye cross brace wire fitting (F11) at each end

before being installed. The fore and aft eyes

are for the cross brace wires in the sides. File

slots in each end of the wooden struts for

receiving the fitting. Cut the slots to a depth

FIG. 3-4 COMPLETED FUSELAGE SIDE

1/16"-THICK STRUTS

F11

LONGERONS

1/16" X 3/32"

1/16" SQUARE STRUTS

1/16" SQUARE

STRUTS

3/32" THIS WAY

TYPICAL SHIMS

TO KEEP

PARTS OFF

PLAN

equal to the thickness of the fitting. Glue the

fittings in place with super glue. Finally,

bend the eyes down on each end to the angle

of the cross brace wires

(Figure 3-3)

.

The tailpost will be installed later between

the two fuselage sides, after the sides are in

the jig.

Start at the forward end of the fuselage and

glue all the struts to the longerons. Careful

you don’t get any globs of glue into the eyes

of the rigging fittings.

Figure 3-4

illustrates

one completed side assembly.

3. Placing the Sides in the

Building Jig

Set both sides in the building jig. Make sure

both sides are aligned. The distance from the

top front of the upper longerons to the face

of the first building jig former should be 1/2".

Hold the sides against the jig formers with

rubber bands

(Figure 3-5)

. Again, check the

alignment of the sides. A little care here will

eliminate a crooked fuselage.

A lot of work can be done on the fuselage

with it in the jig. You may need to remove

the fuselage at times, add some details, and

replace it in the jig. It’s really up to you what

you can accomplish with it in the jig. Do as

much as you can.

4. Building and Installing the

Horizontal Struts

At Station 1 there is no wooden strut. The

nose plate (F14) will do this job and is dis-

cussed later.

At Station 2, there is a 1/16" square strut

only at the bottom of the fuselage. This strut

requires a double end rig fitting for the bot-

tom cross brace wires. The detail is similar to

the rear side struts as shown in

Figure 3-3

.

At Station 3, the top strut is actually a sup-

port beam for the engine bearers that will

be discussed later. The bottom strut is 1/16"

square. In addition, add 1/16" support blocks

at each end of the strut. These blocks sup-

port the forward landing gear struts. Into

the blocks add R1 fittings for the cross brace

wires

(Figure 3-6)

.

At Station 4 and 5, at the top, there is a 1/16"

square strut with no fittings. Note that the

strut at Station 5 is located at the back end

of the side struts. This provides clearance for

Содержание CURTISS JN-4D JENNY

Страница 39: ...PHOTOS OF MODEL AIRWAYS JENNY 39...