11-10

•

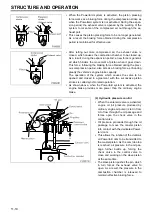

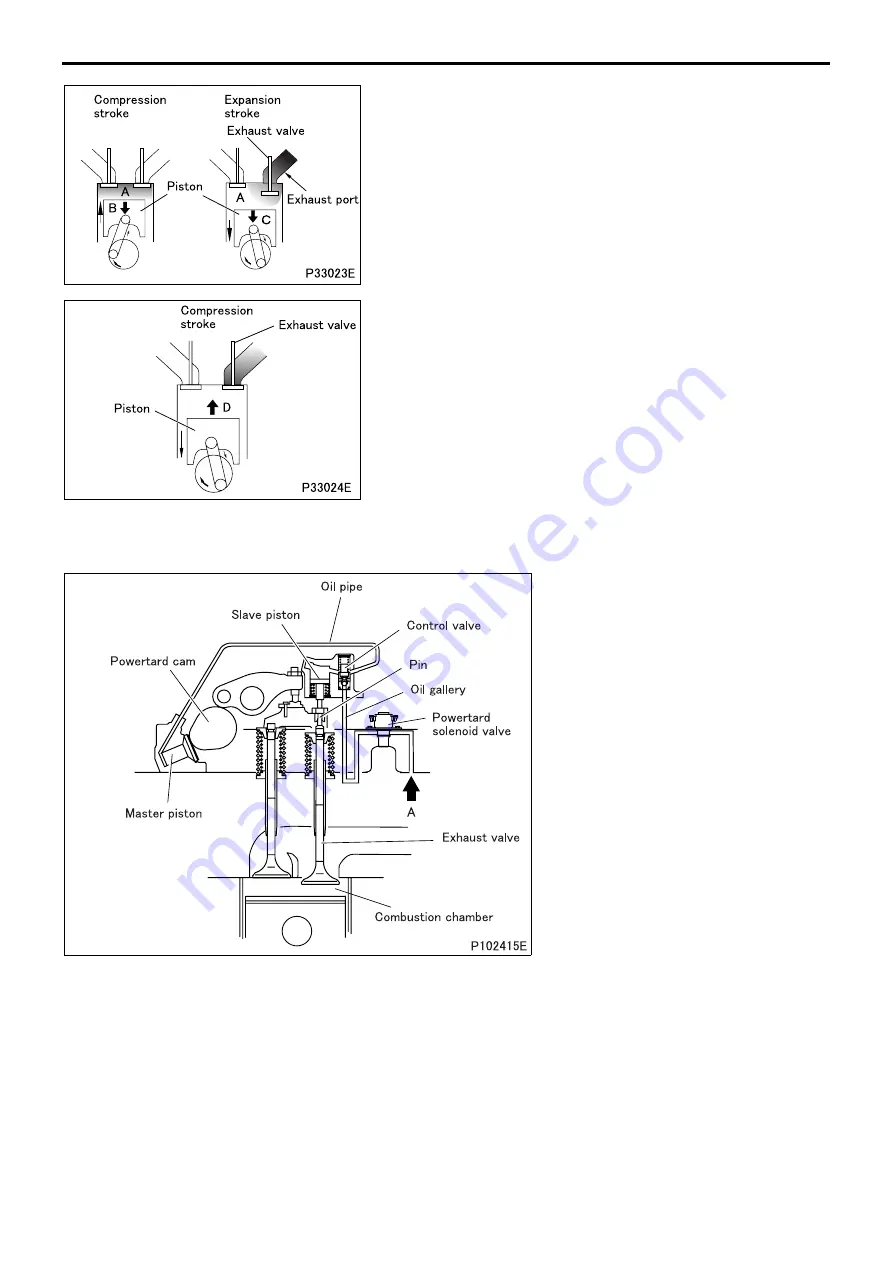

When the Powertard system is activated, the piston pressing

force works as a braking force during the compression stroke as

when the Powertard system is not activated. During the expan-

sion period, the exhaust valve is opened by the working of the

system to let some of the compressed air out through the ex-

haust port.

•

This causes the piston pressing force to be no longer generated.

As a result, the braking force obtained during the compression

period is maintained for effective use.

•

After letting out more compressed air, the exhaust valve is

closed, which causes the combustion chamber to be closed up.

As a result, during the expansion period, a new force is generat-

ed which hinders the movement of piston when it goes down.

This force, following the braking force obtained during the previ-

ous compression period, also acts as a braking force, enhancing

greatly the vehicle’s engine brake capacity.

The operation of the system which causes the valve to be

opened and closed in agreement with the successive piston

strokes is called synchronized operation.

•

As shown above, when the Powertard system is activated, the

engine brake provides more power than the ordinary engine

brake.

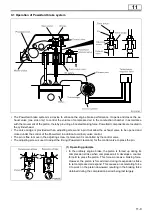

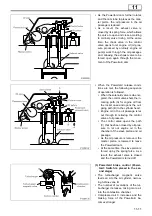

(2) Hydraulic pressure control

•

When the solenoid valve is activated,

engine oil (oil pressure produced by

ordinary engine oil pump) is let in from

A to flow through the oil passage and

forces open the check valve in the

control valve.

•

Oil pressure proceeds through the oil

passage to move the master piston

into contact with the dedicated Power-

tard cam.

•

This allows the rotation of the dedicat-

ed Powertard cam to be transmitted to

the master piston. As the cam lobe top

is reached, oil pressure in the oil pas-

sage further builds up, forcing the

check valve in the control valve to

close and working on the slave piston

at the same time.

•

The slave piston pushes the pin, which

in turn forces the exhaust valve to

open. As a result, the pressure in the

combustion chamber is released to

maintain effective braking force.

STRUCTURE AND OPERATION

Содержание 6M70

Страница 29: ...M E M O 11 19 11 ...

Страница 35: ...M E M O 11 25 11 ...

Страница 36: ...11 26 MITSUBISHI 6M70 ROCKER COVER ROCKER AND SHAFT ...

Страница 40: ...11 30 MITSUBISHI 6M70 CAMSHAFT AND ROCKER CASE ...

Страница 47: ...M E M O 11 37 11 ...

Страница 48: ...11 38 MITSUBISHI 6M70 CYLINDER HEAD AND VALVE MECHANISM ...

Страница 63: ...M E M O 11 53 11 ...

Страница 71: ...M E M O 11 61 11 ...

Страница 77: ...M E M O 11 67 11 ...

Страница 81: ...M E M O 11 71 11 ...

Страница 98: ...11 88 MITSUBISHI 6M70 CRANKSHAFT AND CRANKCASE ...

Страница 127: ...M E M O 12 21 12 ...

Страница 129: ...M E M O 12 23 12 ...

Страница 135: ...M E M O 13 3 13 ...

Страница 138: ...13 6 1 1 Mitsubishi 6M70 Supply pump STRUCTURE AND OPERATION ...

Страница 150: ...13 18 10 Electronic control unit connection diagram STRUCTURE AND OPERATION ...

Страница 151: ...13 13 19 ...

Страница 155: ...M E M O 13 23 13 ...

Страница 185: ...M E M O 13 53 13 ...

Страница 189: ...M E M O 13 57 13 ...

Страница 205: ...M E M O 13 73 13 ...

Страница 211: ...M E M O 13 79 13 ...

Страница 215: ...M E M O 13 83 13 ...

Страница 219: ...M E M O 13 87 13 ...

Страница 225: ...M E M O 13 93 13 ...

Страница 226: ...13 94 INSTALLED LOCATIONS OF PARTS ...

Страница 227: ...13 13 95 ...

Страница 228: ...13 96 INSTALLED LOCATIONS OF PARTS ...

Страница 229: ...13 13 97 ...

Страница 230: ...13 98 INSTALLED LOCATIONS OF PARTS ...

Страница 231: ...13 13 99 ...

Страница 232: ...13 100 MITSUBISHI 6M70 INSTALLED LOCATIONS OF PARTS ...

Страница 233: ...13 13 101 ...

Страница 234: ...13 102 ELECTRIC CIRCUIT DIAGRAM ...

Страница 235: ...13 13 103 ...

Страница 236: ...13 104 ELECTRIC CIRCUIT DIAGRAM ...

Страница 237: ...13 13 105 ...

Страница 238: ...13 106 ELECTRIC CIRCUIT DIAGRAM ...

Страница 241: ...14 14 3 1 Mitsubishi 6M70 Cooling System Flow of Coolant STRUCTURE AND OPERATION ...

Страница 252: ...14 14 Periphery of Engine DISCONNECTION AND CONNECTION OF HOSES AND PIPES ...

Страница 271: ...M E M O 14 33 14 ...

Страница 286: ...M E M O 15 13 15 ...

Страница 295: ...15 22 7 Installed Locations of Parts TURBOCHARGER CONTROL SYSTEM ...

Страница 296: ...15 15 23 ...

Страница 297: ...15 24 TURBOCHARGER CONTROL SYSTEM ...

Страница 298: ...15 15 25 ...

Страница 299: ...15 26 TURBOCHARGER CONTROL SYSTEM ...

Страница 300: ...15 15 27 ...

Страница 301: ...15 28 TURBOCHARGER CONTROL SYSTEM ...

Страница 302: ...M E M O 15 29 15 ...

Страница 303: ...15 30 8 Electric Circuit Diagram TURBOCHARGER CONTROL SYSTEM ...

Страница 304: ...15 15 31 ...

Страница 305: ...15 32 TURBOCHARGER CONTROL SYSTEM ...

Страница 306: ...M E M O 15 33 15 ...

Страница 330: ...M E M O 15 57 15 ...

Страница 340: ...17 6 1 3 Electronic control unit connection diagram STRUCTURE AND OPERATION ...

Страница 343: ...M E M O 17 9 17 ...

Страница 351: ...M E M O 17 17 17 ...

Страница 352: ...17 18 8 Installed Locations of Parts EXHAUST GAS RECIRCULATION SYSTEM ...

Страница 353: ...17 17 19 ...

Страница 354: ...17 20 EXHAUST GAS RECIRCULATION SYSTEM ...

Страница 355: ...17 17 21 ...

Страница 356: ...17 22 EXHAUST GAS RECIRCULATION SYSTEM ...

Страница 357: ...17 17 23 ...

Страница 358: ...17 24 9 Electric Circuit Diagram EXHAUST GAS RECIRCULATION SYSTEM ...

Страница 359: ...17 17 25 ...

Страница 360: ...17 26 MITSUBISHI 6M70 EGR VALVE EGR MAGNETIC VALVE EGR PIPE AND EGR COOLER ...