6

– English

English

4

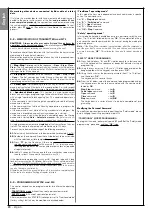

A

A

B

B

3

264 mm

78 mm

288 mm

176 mm

STEP 3

PRELIMINARY INSTALLATION WORK

Before proceeding with installation, check the condition of the product

components, suitability of the selected model and conditions of the

intended installation environment.

IMPORTANT

– The gearmotor cannot be used to power a manual

gate that does not have a fully efficient and safe mechanical struc-

ture. Neither can it solve defects caused by poor installation or insuf-

ficient maintenance of the door itself.

3.1

– CHECKING SUITABILITY OF THE ENVIRONMENT

AND THE GATE TO BE AUTOMATED

• Ensure that the mechanical structure of the gate complies with current

national standards and that it is suitable for automation.

(If present, refer

to the information specified on the gate dataplate)

.

• Move the gate leaf manually to

open

and

close

, checking that move-

ment has the same degree of friction throughout all points of travel

(no

increase in friction must occur)

.

• Manually move the leafs to any position and leave stationary, ensuring

that they do not move from this position.

• Ensure that the space around the gearmotor enables safe and easy

manual gate release. (see chapter “

Manually releasing or locking the

gearmotor

” in the “Operation manual”).

• Ensure that the selected surfaces for installation of the various devices

are solid and guarantee a stable fixture.

• Ensure that all devices to be installed are in a sheltered location and pro-

tected against the risk of accidental impact.

• Ensure that the selected surfaces for fixing the photocells are flat and

enable correct alignment between photocells.

3.2

– CHECKING PRODUCT APPLICATION LIMITS

To ascertain suitability of the product with respect to the specific features

of the gate and area to be automated, the following checks should be per-

formed as well as a check for compliance of the technical data in this

paragraph and the chapter “

Product technical specifications

”.

IMPORTANT – For the checks below, refer also to

fig. 3

and

4

:

–

Fig. 3

: indicates the overall dimensions of the gearmotor.

–

Fig. 4

: indicates values

A

and

B

, i.e. the minimum and maximum meas-

urements to observe when locating the position for the foundation plate.

Note

–

These measurements also serve as a reference to calculate the

space occupied by the foundation pit for routing the electrical cable ducting.

• Ensure that the dimensions and weight of the gate are within the follow-

ing limits of use.

-

maximum length 5 m

(

*

);

-

maximum weight 300 kg

.

(

*

)

Note

– The e rack supplied with this product is suitable for automation

of a gate with leafs of a maximum length of 4 m. If necessary, this may be

extended to a maximum length of 5 m using rack mod. MR1 (2 sections of

50 cm).

• Ensure that the dimensions of the selected area for mounting the gear-

motor is compatible with the overall dimensions.

• On the gate leaf, ensure that the surface for mounting the rack is suit-

able and solid.

CAUTION!

– If the results of these checks do not conform to

specifications, this model cannot be used for automation of

your gate.

30 mm

30 mm

40 mm

40 mm

Left-hand positioning of the gearmotor

Right-hand positioning of the gearmotor