English –

25

AUTOMATION TESTING

1

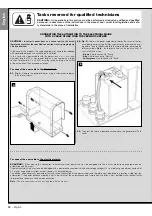

Ensure that all specifications in STEP 1 regarding safety have been

strictly observed.

2

Using the transmitter, perform gate opening and closing tests and

ensure that the leaf movement corresponds to specifications.

Test several times to assess smooth operation of the gate and check

for any defects in assembly or adjustment and any possible points of

friction.

3

Check operation of all system safety devices one at a time (photocells,

sensitive edges, etc.). Photocells: Activate a single pair of photocells

during a manoeuvre (see

Table 2

to identify which manoeuvre to per-

form) and check that the control unit stops the manoeuvre and acti-

vates a total inversion of the movement (the flashing light emits 2 flash-

es, twice). Sensitive edges: Activate the device during an

Opening

or

Closing

manoeuvre and check that the control unit stops the manoeu-

vre and activates a brief inversion of the movement (the flashing light

emits 2 flashes, twice).

4

To check the photocells, and to ensure there is no interference with oth-

er devices, pass a cylinder (diameter 5 cm, length 30 cm) through the

optic axis joining the pair of pho-

tocells (

fig. 45

): pass the cylinder

first close to the TX photocell,

then close to the RX and lastly at

the centre between the two .

Ensure that in all cases the device

engages, changing from the

active status to alarm status and

vice versa, and that the envis-

aged action is generated in the

control unit (for example move-

ment inversion in the

Closing

manoeuvre).

5

Measure the force as specified in the standard EN 12445. If the motor

force control is used by the control unit as an auxiliary function for

reduction of impact force, adjust the functions “Leaf movement speed”

and “Leaf deceleration points” (Chapter 10) to identify the setting that

obtains the best results.

CAUTION!

– If the gate weighs more than 200

kg, to ensure compliance with the parameters in the standard EN

12453, a flexible edge must be fitted at the end of the gate.

6

To check operation of the buffer battery, on completion of charging, test

as follows: disconnect the power supply and after a few seconds check

that the leds and flashing light emits a series of 5 flashes. If this does

not occur, check that the battery connector is correctly inserted and

invert if necessary.

AUTOMATION COMMISSIONING

Commissioning can only be performed after positive results of all test

phases. Partial or “makeshift” commissioning is strictly prohibited.

1

Prepare the automation technical documentation, which must contain

the following documents: Overall layout drawing (see example in

fig. 5

),

and electrical connection layout diagram (see example

fig. 17

) risk

assessment and relative solutions adopted (see the website

www.moovo.com

for a guide to risk assessment for different types of

gates), manufacturer’s declaration of conformity for all devices used

and the declaration of conformity compiled by the installer (see section

TECHNICAL DOCUMENTATION).

2

Affix a dataplate on the door, specifying at least the following data: type

of automation, name and address of manufacturer (responsible for

commissioning), serial number, year of construction and CE mark.

3

Prepare and provide the owner with the declaration of conformity; the

“

CE Declaration of conformity

”

in the section TECHNICAL DOCU-

MENTATION must be compiled for this purpose.

4

Prepare and provide the owner with the form

“

Operation manual

”

in

the section TECHNICAL DOCUMENTATION .

5

Prepare and provide the owner with the form

“

Maintenance schedule

”

in the section TECHNICAL DOCUMENTATION, containing all mainte-

nance instructions for all devices in the automation .

6

Before commissioning the automation, ensure that the owner is ade-

quately informed of all associated risks and hazards.

AUTOMATION TESTING AND COMMISSIONING

These are the most important phases of automation set-up to ensure maximum system safety.

The testing procedure described can also be performed as a periodic check of automation devices.

Testing and commissioning of the automation must be performed by skilled and qualified personnel, who are responsible for the tests required to veri-

fy the solutions adopted according to the risks present, and for ensuring observance of all legal provisions, standards and regulations: and in particular

all requirements of the standard EN 12445, which establishes the test methods for checking automations for gates.

PRODUCT DISPOSAL

45

PERIODIC MAINTENANCE OPERATIONS

This product does not generally require any special maintenance; never-

theless, regular check-ups are advisable to ensure the system is in good

working order and that the safety devices installed work properly.

To carry out this maintenance correctly, please refer to the

“

Maintenance

Schedule

”

, which you will find in the “TECHNICAL DOCUMENTATION”

section at the end of the manual.

This product is an integral part of the automation and therefore must

be disposed together with the latter.

As in installation, also at the end of product lifetime, the disassembly and

scrapping operations must be performed by qualified personnel.

This product comprises various types of materials: some may be recycled

others must be disposed of. Seek information on the recycling and dis-

posal systems envisaged by the local regulations in your area for this

product category.

Caution!

– some parts of the product may contain pollutant or hazardous

substances which, if disposed of into the environment, may cause serious

damage to the environment or physical health.

As indicated by the symbol alongside, disposal of

this product in domestic waste is strictly prohibited

Separate the waste into categories for disposal,

according to the methods envisaged by current

legislation in your area, or return the product to the

retailer when purchasing a new version.

Caution!

- Local legislation may envisage serious fines in the event of

abusive disposal of this product.

English